In the dynamic world of manufacturing, where efficiency and precision are paramount, the introduction of the Automation Takeup Robotic Arm has marked a significant leap forward. This advanced robotic technology is transforming the industry by streamlining processes, reducing waste, and increasing productivity. As companies grapple with the challenges of a global market that demands faster production times and higher quality standards, the Automation Takeup Robotic Arm stands out as a key solution.

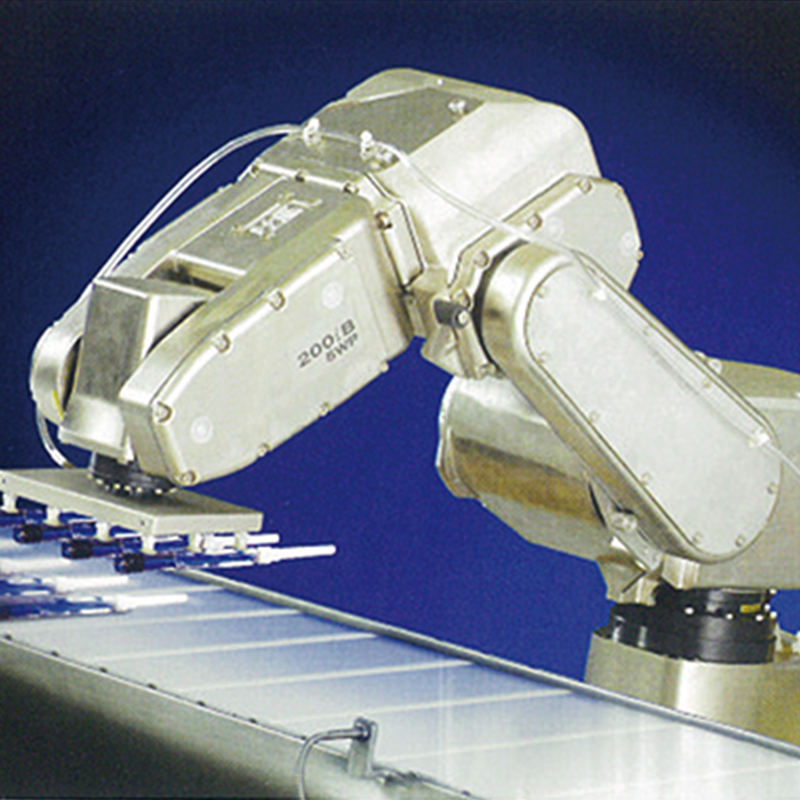

The Automation Takeup Robotic Arm is a advanced piece of equipment designed to handle the complex task of take-up in automated systems. This refers to the process of managing the movement and storage of material, such as cable, wire, or hose, as it is fed through a machine or during assembly. Traditionally, take-up has been a manual process, prone to errors and inefficiencies. However, with the advent of the Automation Takeup Robotic Arm, these issues are a thing of the past.

One of the key advantages of the Automation Takeup Robotic Arm is its adaptability. It can be customized to suit a wide range of materials and applications, from the smallest wires to larger hoses. This flexibility allows manufacturers to automate a variety of processes, from electronics assembly to automotive part production. The robotic arm's sophisticated control systems also enable it to learn from its environment, making real-time adjustments to ensure ideal performance.

The precision offered by the Automation Takeup Robotic Arm is another standout feature. With advanced sensors and algorithms, these robotic arms can make minute adjustments to maintain the desired tension and speed, ensuring consistent quality across all products. This level of accuracy is particularly important in industries where the slightest variation can cause product failure or safety concerns.

As the global market becomes more competitive, the need for automation in manufacturing is growing. The Automation Takeup Robotic Arm is at the forefront of this trend, providing a solution that is both cost-effective and scalable. Companies that invest in this technology are not only improving their current operations but also future-proofing their businesses against the challenges of an ever-changing market.

The impact of the Automation Takeup Robotic Arm extends beyond the factory floor. It also has significant implications for the environment. By reducing waste and improving material utilization, these robotic arms contribute to more sustainable manufacturing practices. This is particularly important as consumers and regulators alike demand more eco-friendly production methods.

Training and skill development are also key areas where the Automation Takeup Robotic Arm is making a difference. As the technology becomes more prevalent, there is a growing need for skilled technicians who can operate and maintain these advanced systems. This is creating new job opportunities and driving the demand for education and training programs that focus on automation and robotics.

The Automation Takeup Robotic Arm is a powerful tool that is reshaping the manufacturing industry. Its ability to improve efficiency, precision, and sustainability makes it an essential investment for companies looking to stay competitive in today's global market. As technology continues to advance, the Automation Takeup Robotic Arm will undoubtedly play a central role in driving innovation and enhancing the capabilities of manufacturing operations worldwide.

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى