With the continuous development of technology, the demand for various equipment and systems in factory production processes is also constantly increasing. To meet the needs of modern production, factories need to plan and select various types of equipment and systems. This article will classify and describe three types of equipment: water and gas systems, centralized material supply systems, and AGV intelligent digital warehousing. It will include their characteristics, application areas, classifications, and cautions for selection.

Water and Gas Systems:

1. Features:

Water and gas systems are indispensable infrastructure in factory production processes, mainly including water supply and drainage systems, power supply systems, and gas supply systems. These systems provide factories with stable energy supplies and good production environments.

2. Application areas:

Water and gas systems are widely used in various factories, such as food processing, chemical, machinery manufacturing, and other industries.

3. Classification:

According to function and usage scenarios, water and gas systems can be classified into the following categories:

(1) Water supply and drainage systems: including water supply systems, drainage systems, and sewage treatment systems.

(2) Power supply systems: including transformers, power distribution cabinets, cables, and other equipment.

(3) Gas supply systems: including air compressors, gas storage tanks, pipes, and other equipment.

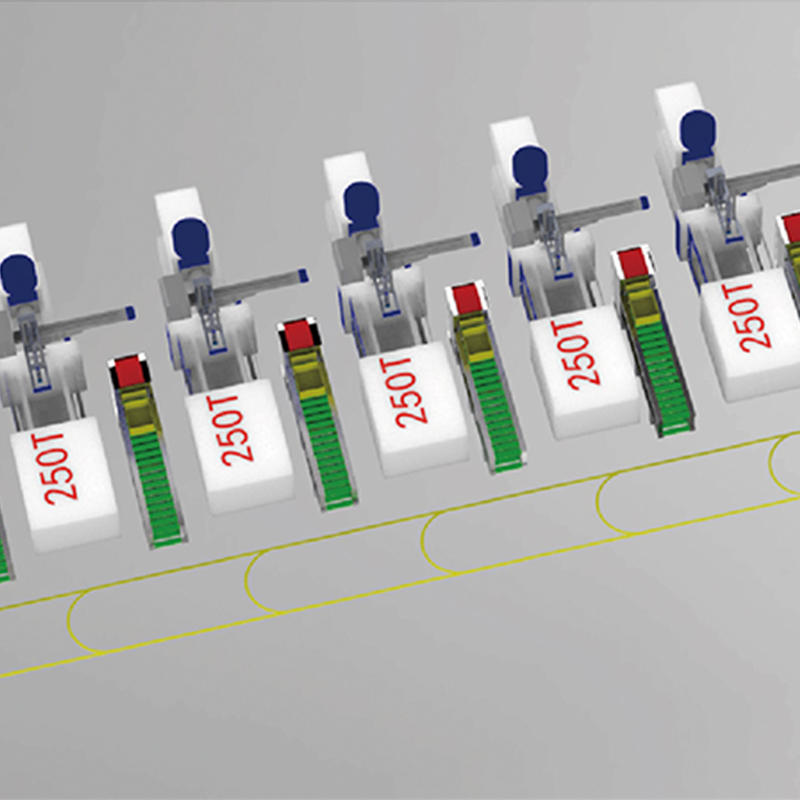

Centralized Material Supply System:

1. Features:

A centralized material supply system is an automated material handling system that transports raw materials from storage areas to production lines through conveying equipment. It can realize fast, accurate, and efficient supply of raw materials, improving production efficiency.

2. Application areas:

Centralized material supply systems are widely used in various factories, such as food processing, chemical, and pharmaceutical industries.

3. Classification:

According to function and usage scenarios, centralized material supply systems can be classified into the following categories:

(1) Powder supply system: mainly used for the transportation of powdery raw materials.

(2) Granular supply system: mainly used for the transportation of granular raw materials.

(3) Liquid supply system: mainly used for the transportation of liquid raw materials.

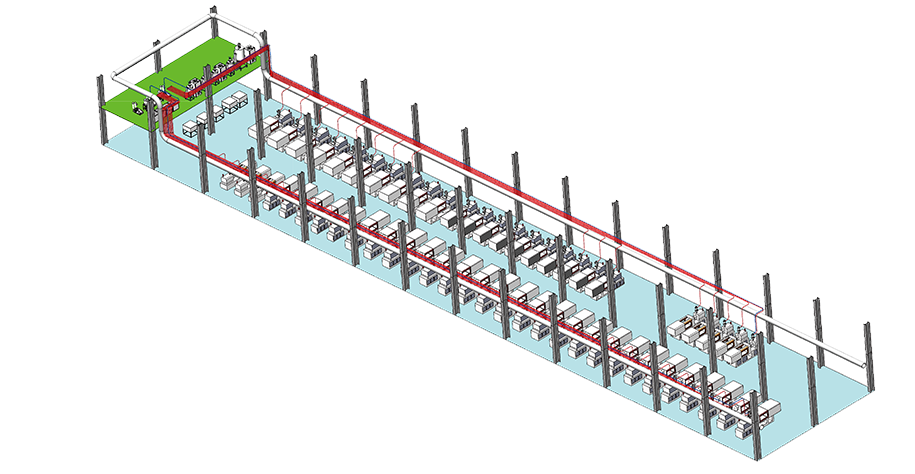

AGV Intelligent Digital Warehousing:

1. Features:

AGV intelligent digital warehousing is a system that utilizes automatic guided vehicle (AGV) technology to realize automated material handling and storage within warehouses. It has the advantages of high intelligence, high automation, and cost savings in manpower.

2. Application areas:

AGV intelligent digital warehousing is widely used in various factories, such as e-commerce logistics, automobile manufacturing, home appliance manufacturing, and other industries.

3. Classification:

According to function and usage scenarios, AGV intelligent digital warehousing can be classified into the following categories:

(1) Rack-type AGV: mainly used for material handling on shelves.

(2) Floor-type AGV: mainly used for material handling on the ground.

(3) Submerged-type AGV: mainly used for material handling by submerging into shelves.

Important Notes for Selection:

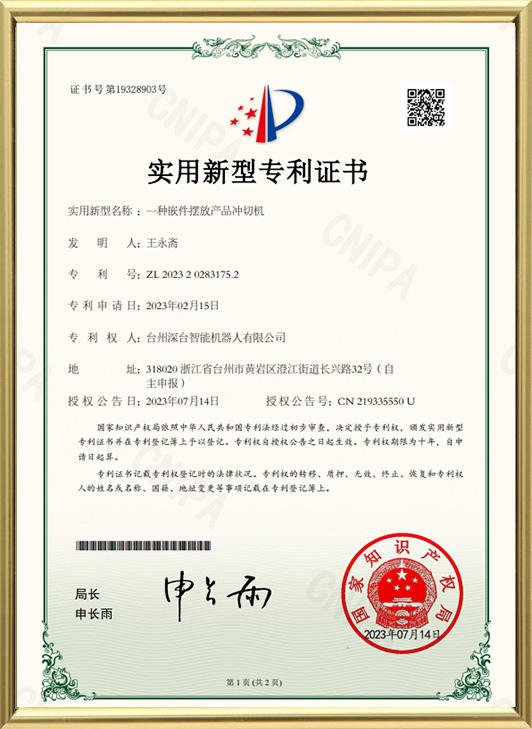

1. Choose suppliers with good quality and reputation.

2. Select suitable equipment and specifications based on the actual needs of the factory.

3. Consider the energy consumption and maintenance costs of the equipment.

Summary:

This article provides a classification description of three types of equipment: water and gas systems, centralized material supply systems, and AGV intelligent digital warehousing, including their characteristics, application areas, classifications, and important notes for selection. When factories select equipment, they should consider factors such as quality, performance, and price based on their own needs and budgets, and choose suitable equipment and suppliers to improve production efficiency and reduce production costs.

View More

View More

View More

View More

View More

View More

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى