Pipe Welding Robots and Robotic Welding Machines have emerged as game-changers, offering enhanced precision, efficiency, and reliability in welding processes.

The Pipe Welding Robot is specifically designed to address the unique challenges associated with pipe welding, such as complex geometries, tight spaces, and varying joint configurations. These robots are equipped with specialized welding torches, sensors, and programming interfaces that enable them to navigate and weld pipes with precision and accuracy.

One of the key advantages of the Pipe Welding Robot is its ability to perform consistent and high-quality welds on pipes of different sizes, materials, and thicknesses. The robot's advanced sensors and vision systems can detect deviations in weld quality, torch position, or material alignment, allowing for real-time adjustments and ensuring weld integrity.

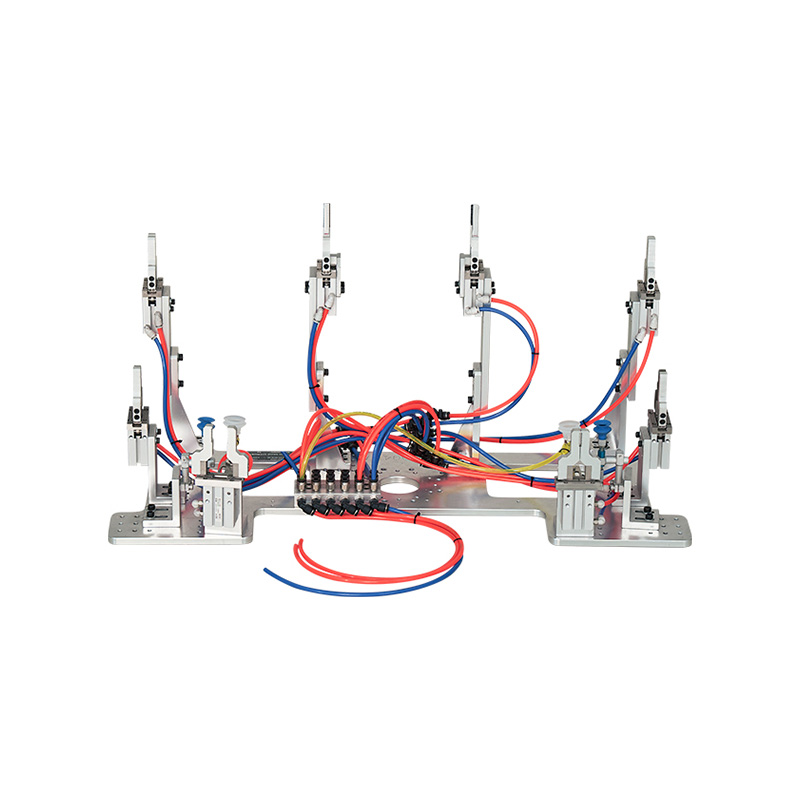

Moreover, Pipe Welding Robots are designed for flexibility and adaptability, with multi-axis articulation that enables them to access hard-to-reach areas and perform complex welding tasks. Whether it's welding elbows, tees, or straight sections, these robots can handle a wide range of pipe configurations with ease.

Additionally, Pipe Welding Robots are equipped with collaborative features that enable them to work alongside human operators safely. The integration of safety sensors, emergency stop buttons, and protective barriers ensures a safe and productive working environment, small the risk of accidents or injuries.

The Robotic Welding Machine represents a broader category of robotic welding solutions designed to automate various welding processes across different industries. These machines are equipped with robotic arms, welding torches, and control systems that enable them to perform arc welding, MIG welding, TIG welding, and other welding processes with precision and consistency.

One of the distinguishing features of Robotic Welding Machines is their versatility and scalability, making them suitable for a wide range of welding applications, from automotive and aerospace manufacturing to construction and shipbuilding. Whether it's welding automotive chassis, structural beams, or intricate components, these machines can handle diverse welding tasks with ease.

Moreover, Robotic Welding Machines are designed for efficiency and productivity, with high-speed welding capabilities and continuous operation that enable them to complete welding tasks quickly and reliably. This efficiency translates to lower production costs, faster cycle times, and increased throughput, making them a cost-effective solution for high-volume welding operations.

Additionally, Robotic Welding Machines are equipped with advanced control systems and programming interfaces that enable seamless integration with other manufacturing equipment, such as CNC machines, robotic arms, and material handling systems. This integration facilitates automated workflows, reduces manual intervention, and optimizes overall production efficiency.

Pipe Welding Robots and Robotic Welding Machines are revolutionizing the welding industry by offering enhanced precision, efficiency, and reliability in welding processes. Whether it's addressing the unique challenges of pipe welding with specialized robotic solutions or automating diverse welding tasks across different industries with versatile robotic machines, these welding solutions are redefining the boundaries of what's possible in automated welding.

We can expect to see further innovations and enhancements in robotic welding machine design, functionality, and performance. From smarter sensors and adaptive control algorithms to improved safety features and collaborative capabilities, the future of robotic welding is promising, offering new opportunities to optimize processes, reduce costs, and drive innovation in the welding industry.

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى