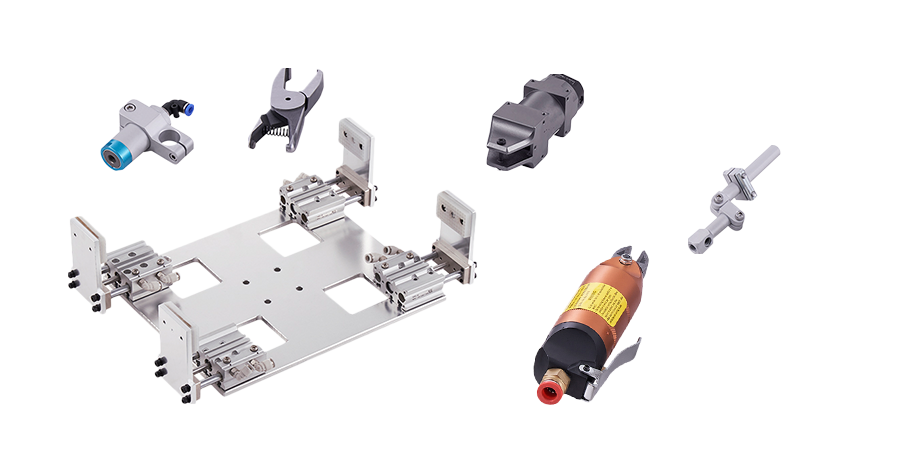

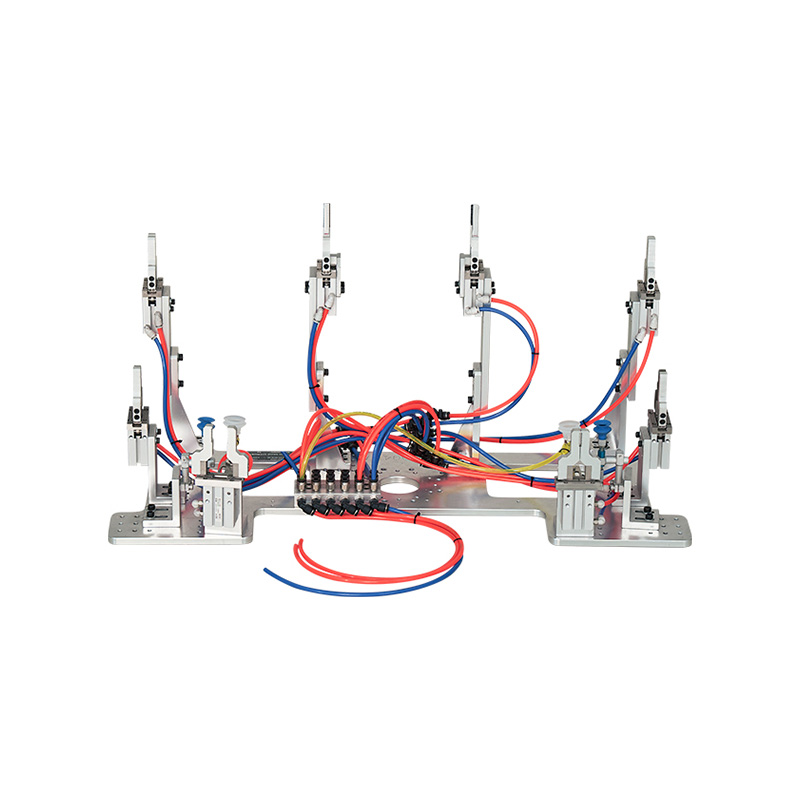

Product Features:

1. High Efficiency Filtration: The vacuum generator/filter check valve is made of high-quality materials and has a high filtration performance, which can effectively remove impurities and contaminants generated by the injection molding machine, ensuring the purity of the injection molding process.

2. Precise Control: This check valve uses advanced control technology to accurately control the vacuum degree and pressure, ensuring the stability of the injection molding machine's operation and product quality.

3. High Durability: The vacuum generator/filter check valve has a reasonable structural design and is made of high-quality materials, with good wear and corrosion resistance, providing a long service life.

4. Easy Installation: The design of the check valve takes into account the convenience of installation, allowing users to easily install and maintain it without professional technicians.

5. Safety and Reliability: The vacuum generator/filter check valve has an overload protection function. When the working pressure exceeds the set value, the valve will automatically close to ensure the safe operation of the equipment.

Product Advantages:

1. Improve Production Efficiency: The vacuum generator/filter check valve can effectively remove impurities and contaminants generated by the injection molding machine, ensuring the purity of the injection molding process, thereby improving production efficiency.

2. Ensure Product Quality: By precisely controlling the vacuum degree and pressure, the vacuum generator/filter check valve can ensure the stability of the injection molding machine's operation, thereby ensuring product quality.

3. Reduce Maintenance Costs: Due to the high durability of the vacuum generator/filter check valve and its long service life, it can reduce user maintenance costs.

4. Enhance Equipment Performance: The vacuum generator/filter check valve is easy to install, allowing users to quickly install and maintain it without professional technicians, thereby enhancing equipment performance.

5. Ensure Equipment Safety: The vacuum generator/filter check valve has an overload protection function. When the working pressure exceeds the set value, the valve will automatically close to ensure the safe operation of the equipment.

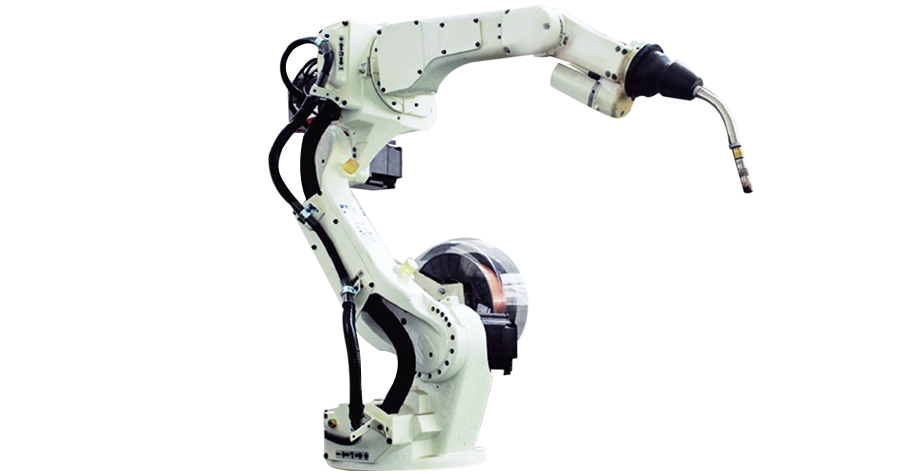

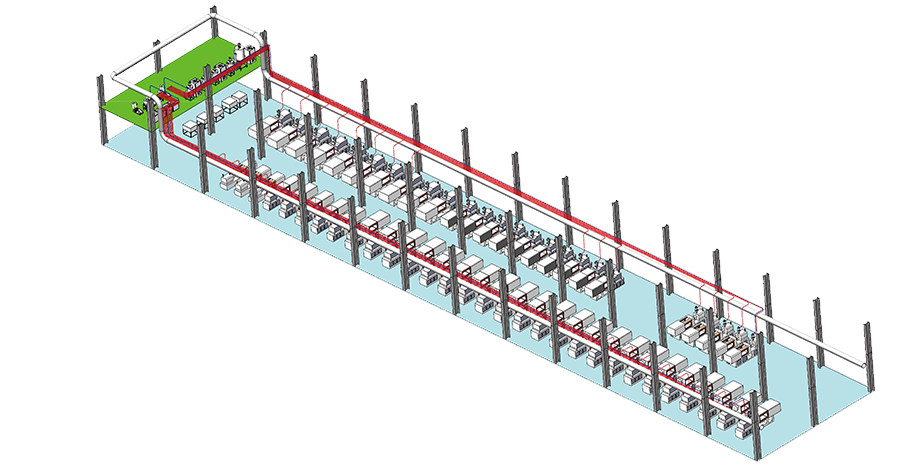

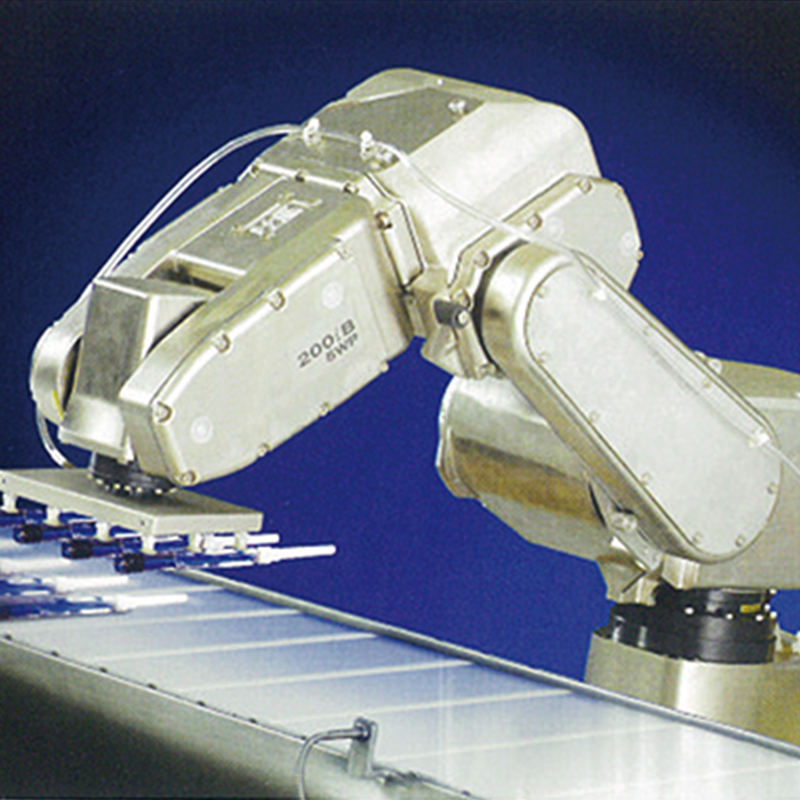

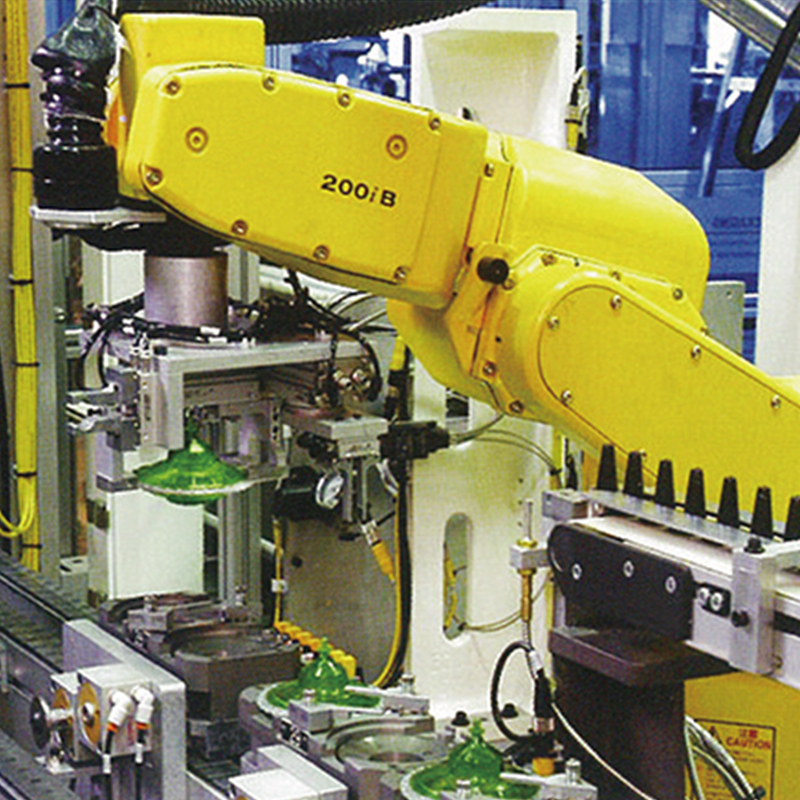

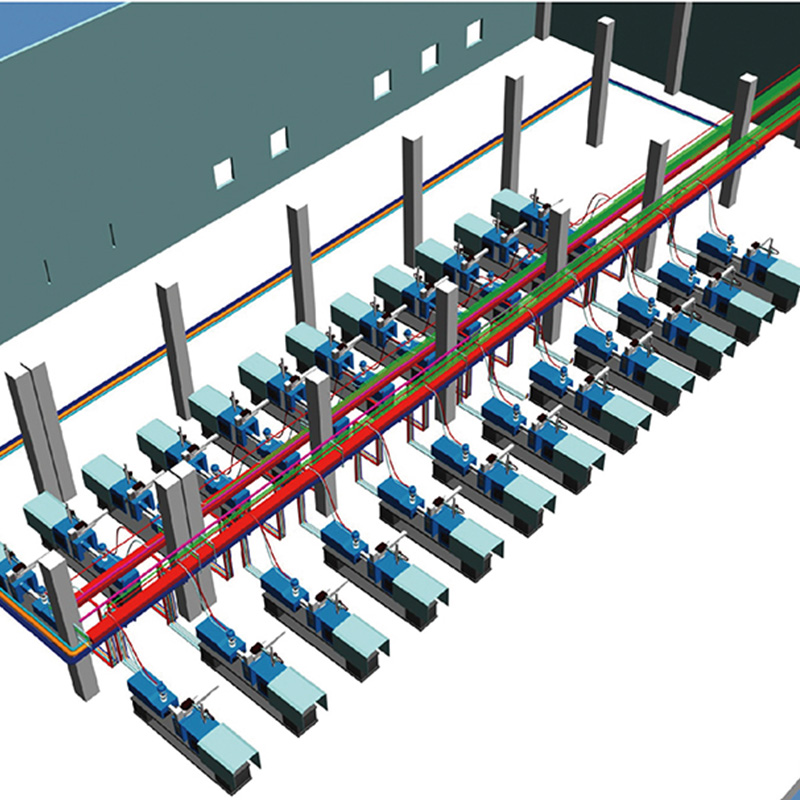

Product Application:

The vacuum generator/filter check valve is an important accessory for the injection molding machine's dedicated manipulator and is widely used in the production process of various injection molding machines. By precisely controlling the vacuum degree and pressure, this valve can effectively remove impurities and contaminants generated by the injection molding machine, ensuring the purity of the injection molding process, thereby improving production efficiency and ensuring product quality.

Product Maintenance:

1. Regularly check the working status of the valve to ensure its normal operation.

2. Regularly clean the impurities and contaminants inside the valve to maintain its filtration performance.

3. Regularly lubricate the valve to extend its service life.

4. If any abnormal conditions are found in the valve, stop using it immediately and repair it in time.

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى