The material handling industry has been continuously evolving to meet the growing demands of various sectors, including manufacturing, logistics, and warehousing. Conveyor systems play a crucial role in streamlining material transportation, reducing manual labor, and improving overall efficiency. We will discuss their design, functionality, and the advantages they offer in modern material handling processes.

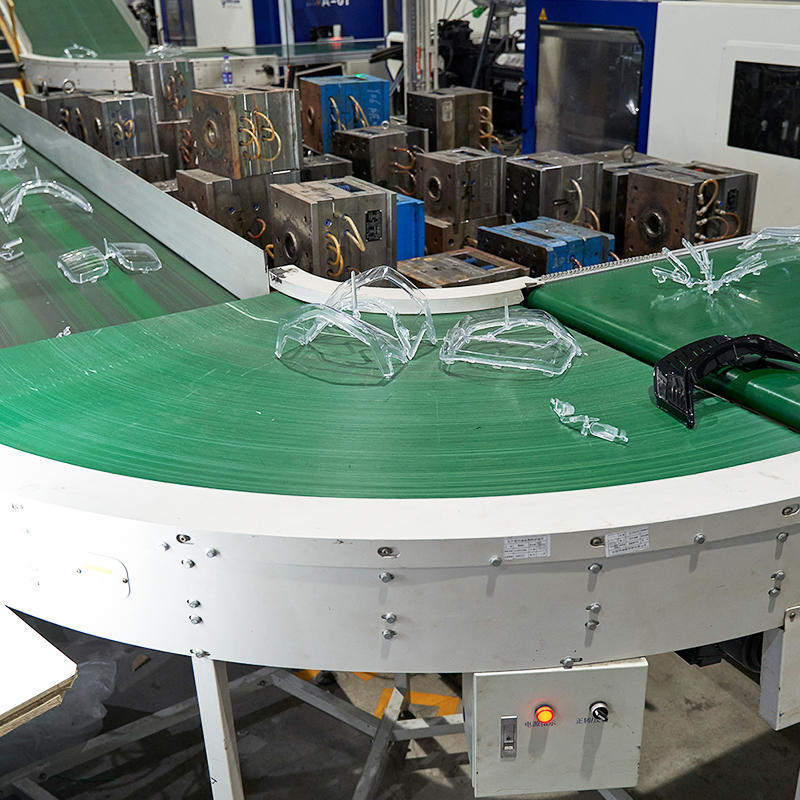

Conveyor roller assemblies are the backbone of any conveyor system, providing support and facilitating the smooth movement of materials along the conveyor line. These assemblies consist of a series of rollers mounted on a frame, which can be customized to suit specific application requirements.

Conveyor roller assemblies are designed to accommodate various load capacities, sizes, and shapes of materials. They can be made from different materials, such as steel, plastic, or aluminum, depending on the application's demands. The rollers can be driven or non-driven, with driven rollers providing additional propulsion to the conveyed items.

- Reduced manual labor: Conveyor roller assemblies small the need for manual handling, reducing the risk of injury and fatigue.

- Improved efficiency: The smooth movement of materials on roller assemblies ensures consistent and efficient transportation.

- Customization: Roller assemblies can be tailored to meet specific requirements, such as load capacity, size, and material type.

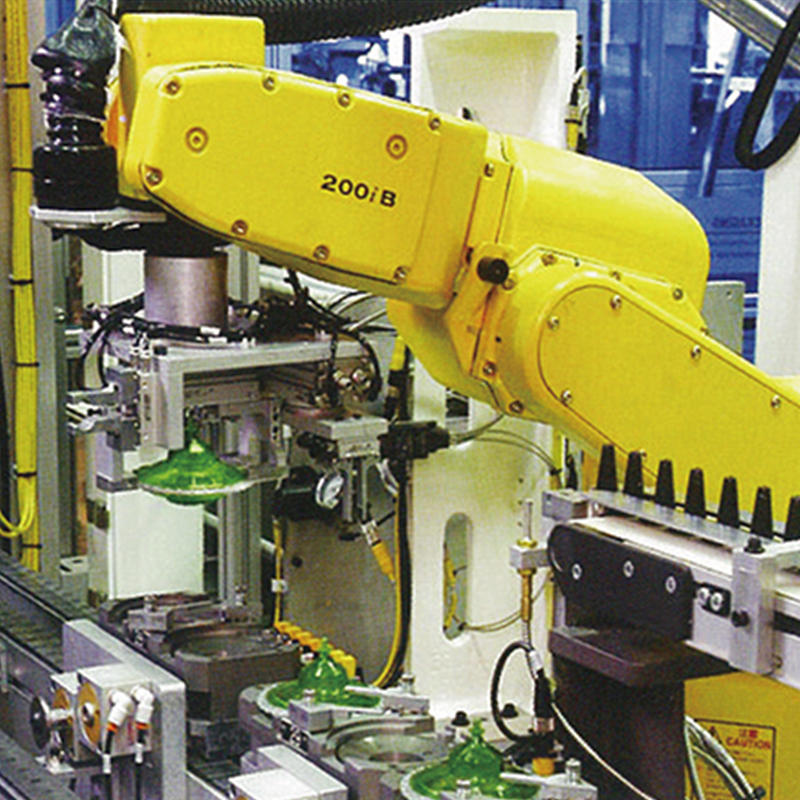

Metal mesh conveyor belts are a versatile and durable solution for transporting delicate, heavy, or high-temperature items. These belts are made from interwoven metal wires, providing a strong and flexible surface for material transportation.

Metal mesh conveyor belts are designed to withstand high temperatures, corrosion, and wear. They can be used in various applications, such as baking, cooling, and freezing processes in the food industry, as well as in the automotive and electronics sectors for parts handling.

- Durability: Metal mesh belts are resistant to wear, corrosion, and high temperatures, making them suitable for harsh environments.

- Versatility: These belts can be used in a wide range of applications, from food processing to heavy-duty manufacturing.

- Hygiene: The open design of metal mesh belts allows for easy cleaning and reduces the risk of contamination.

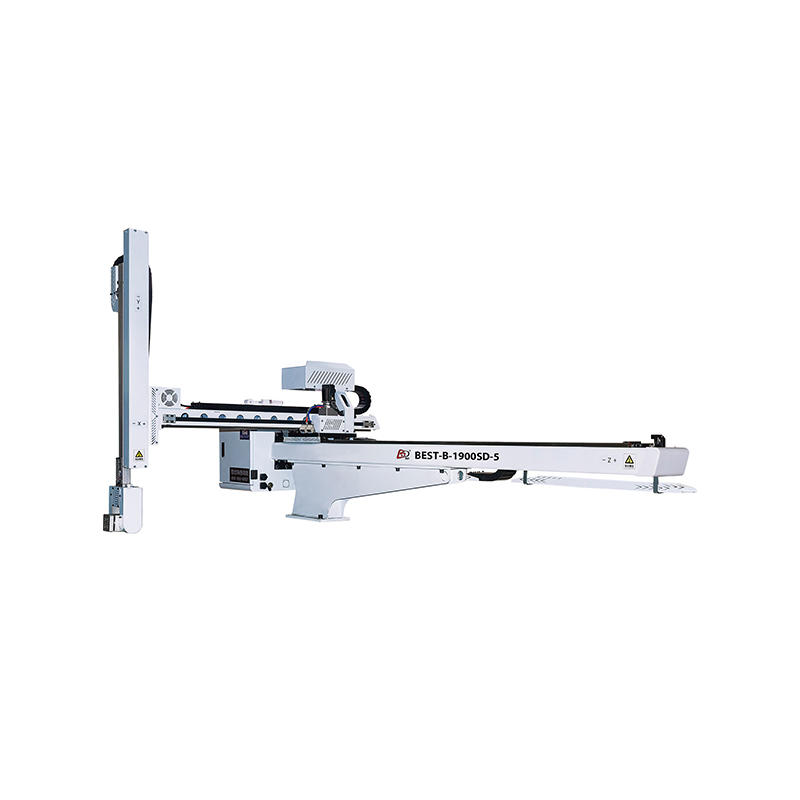

Movable conveyor systems are designed to provide flexibility and adaptability in material handling operations. These systems can be easily reconfigured or relocated to accommodate changing production requirements or to optimize space utilization.

Movable conveyor systems can be motorized or manually operated, depending on the application's needs. They can be designed as modular units, allowing for easy assembly and disassembly. This modularity enables users to customize the conveyor layout to suit specific requirements.

- Flexibility: Movable conveyor systems can be easily reconfigured or relocated to adapt to changing production demands.

- Space optimization: These systems can be designed to big space utilization in confined areas.

- Cost-effectiveness: Movable conveyor systems offer a cost-effective solution for businesses looking to improve material handling efficiency without significant investment.

Conveyor roller assemblies, metal mesh conveyor belts, and movable conveyor systems are essential components of modern material handling operations. Each of these systems offers unique advantages, such as reduced manual labor, improved efficiency, durability, and flexibility. By understanding the design, functionality, and benefits of these components, businesses can make informed decisions when selecting the more suitable conveyor system for their specific needs.

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى