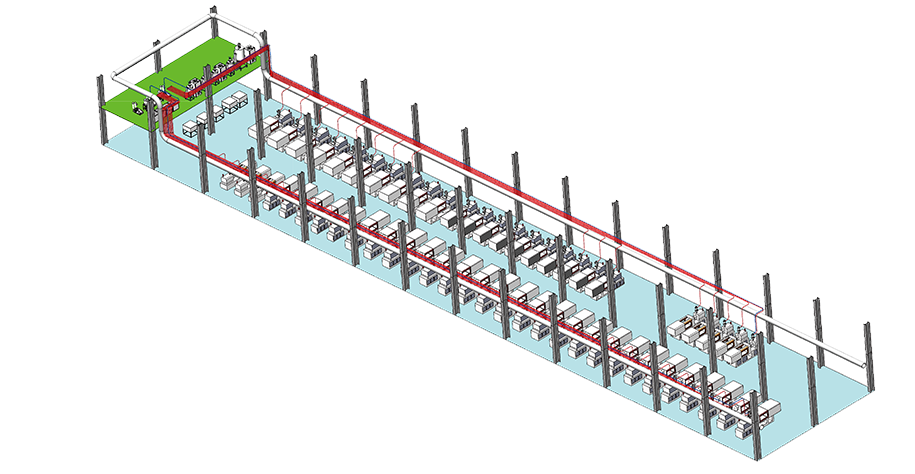

Assembly line is a kind of automation equipment widely used in industrial production, which divides the production process into multiple continuous steps, so that products can be produced at a certain speed and sequence. The emergence of assembly line has greatly improved production efficiency, reduced production costs, and enabled enterprises to better meet market demand. This article will be from the characteristics of the pipeline, application field, classification and purchase precautions four aspects.

Features of the assembly line:

1. High degree of automation: The production line adopts advanced automatic control technology, which can realize the automation of the production process, reduce manual intervention, and improve production efficiency.

2. Flexibility: The assembly line can be adjusted according to the production needs to adapt to different production tasks and processes.

3. Efficiency: The assembly line adopts continuous operation mode, and each production link is closely connected, which reduces the waiting time in the production process and improves the production efficiency.

4. Space saving: The assembly line adopts three-dimensional layout to make full use of space and reduce the floor area in the production process.

5. Easy to manage: the production process of the assembly line is standardized, which is convenient for enterprise management and monitoring, and is conducive to improving product quality.

Application areas of pipeline:

Assembly line is widely used in various fields, such as automobile manufacturing, electronic product assembly, food processing, medical production and so on. Here are some common pipeline application scenarios:

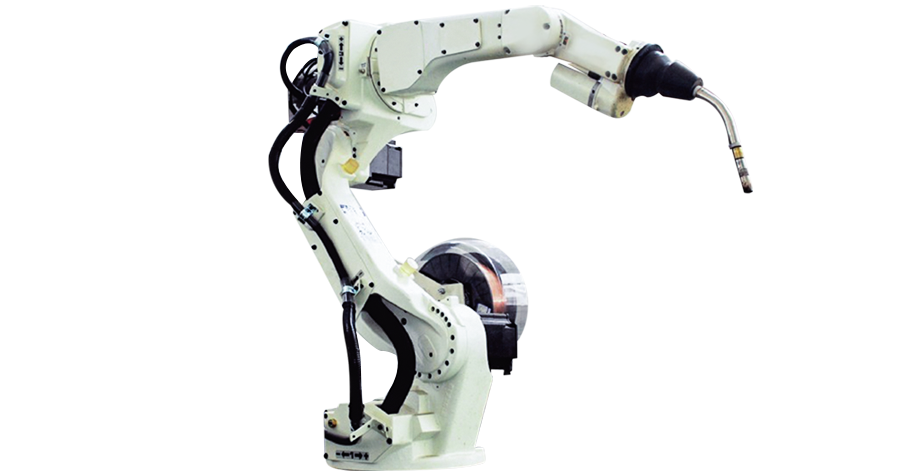

1. Automobile manufacturing: In the automobile manufacturing process, the assembly line can assign the production tasks of engine, chassis, body and other components to different workstations to achieve fast and efficient production.

2. Assembly of electronic products: In the assembly process of electronic products, the assembly line can assign the placement, welding, testing and other processes of electronic components to different workstations to improve production efficiency.

3. Food processing: In the process of food processing, the assembly line can allocate raw material processing, cooking, packaging and other processes to different workstations to ensure food quality and health and safety.

4. Pharmaceutical production: In the process of pharmaceutical production, the assembly line can assign the synthesis, preparation, filling and other processes of raw materials to different workstations to ensure drug quality and production safety.

Classification of pipeline:

According to the different functions and structures, pipelines can be divided into the following categories:

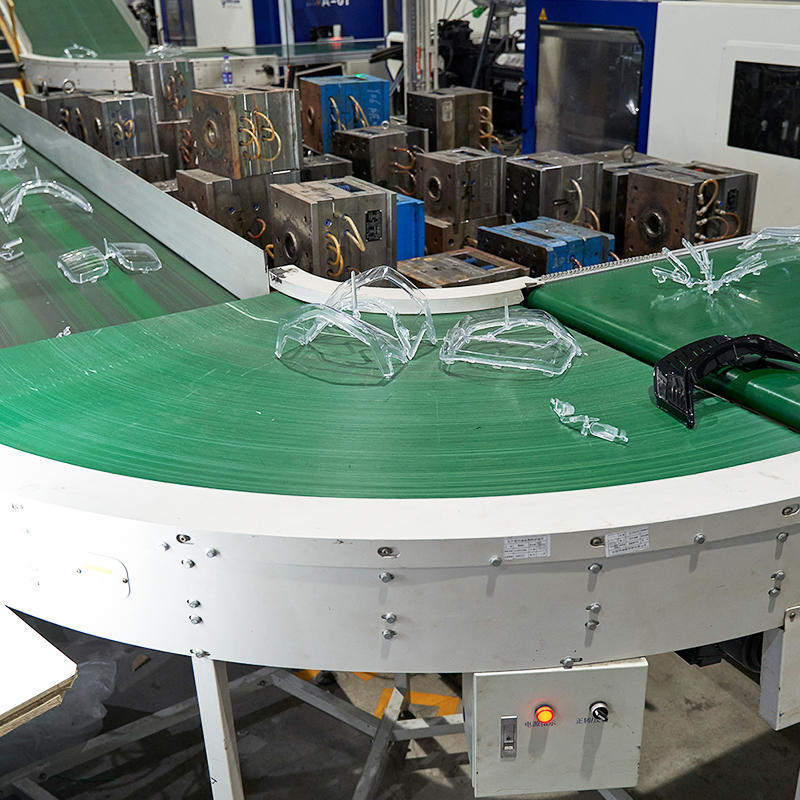

1 belt conveyor belt line: through the belt drive, to achieve the conveying and assembly of materials.

2. Trolley assembly line: The trolley is moved on the track to realize the conveying and assembly of materials.

3. Cross-sitting assembly line: the two workstations are arranged face to face to realize the rapid exchange and assembly of materials.

4. Taiwan plug-in assembly line: The components are inserted into the circuit board through the desktop plug-in machine to realize the assembly of electronic products.

5. Differential chain line: Through differential chain transmission, to achieve the conveying and assembly of materials.

Assembly line purchase precautions:

When purchasing the assembly line, you need to pay attention to the following points:

1. Select the right pipeline type and specification according to the production demand.

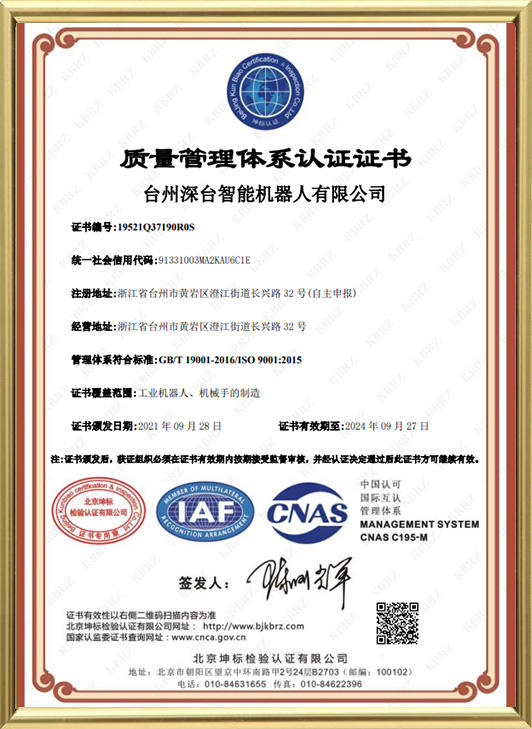

2. Select equipment suppliers with reliable quality and stable performance.

3. Consider the energy consumption and maintenance costs of the equipment.

4. Consider device scalability and compatibility.

5. Consider the safety protection measures and operation convenience of the equipment.

In short, as a highly automated production tool, the assembly line has the characteristics of high efficiency, flexibility and space saving, and is widely used in various fields. When purchasing the assembly line, it is necessary to choose the right type and specifications according to the production needs, and pay attention to the quality, performance, energy consumption and maintenance costs of the equipment. Through rational purchase and use of assembly lines, enterprises can improve production efficiency, reduce production costs, and better meet market demand.

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى