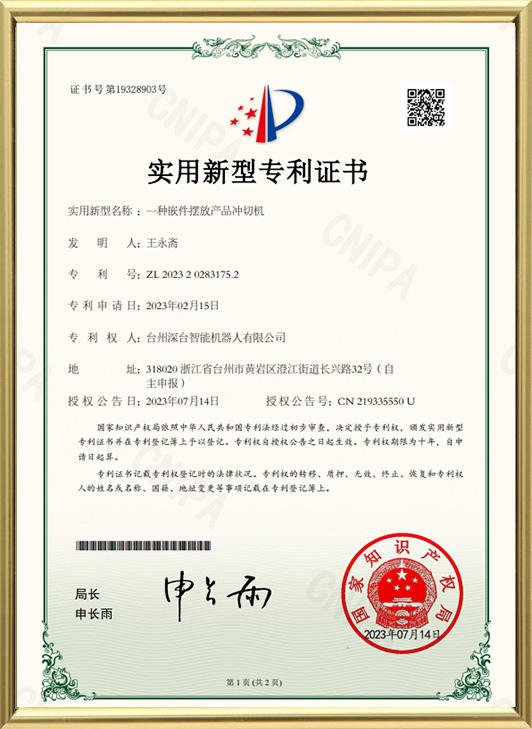

Manipulator components are an indispensable and important part of modern manufacturing. They play a crucial role in automated production lines. This article will provide a detailed explanation of manipulator components from four aspects: features, application fields, classification, and purchasing considerations.

Features:

1. High precision: Manipulator components have the characteristic of high precision, which can meet the production and processing needs of various precision parts.

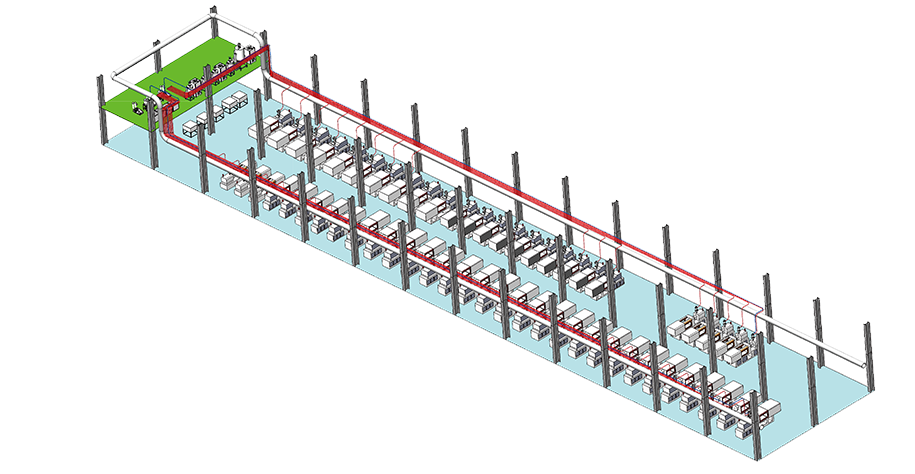

2. High efficiency: Manipulator components can achieve high-speed and efficient production, greatly improving production efficiency and reducing production costs.

3. Good stability: Manipulator components have good stability, maintaining stable working conditions during long-term production processes to ensure product quality.

4. High flexibility: Manipulator components can be flexibly adjusted according to different production needs, adapting to various complex production environments.

5. Easy maintenance: Manipulator components adopt advanced design concepts and manufacturing processes, making installation and maintenance easy, reducing maintenance costs.

Application Fields:

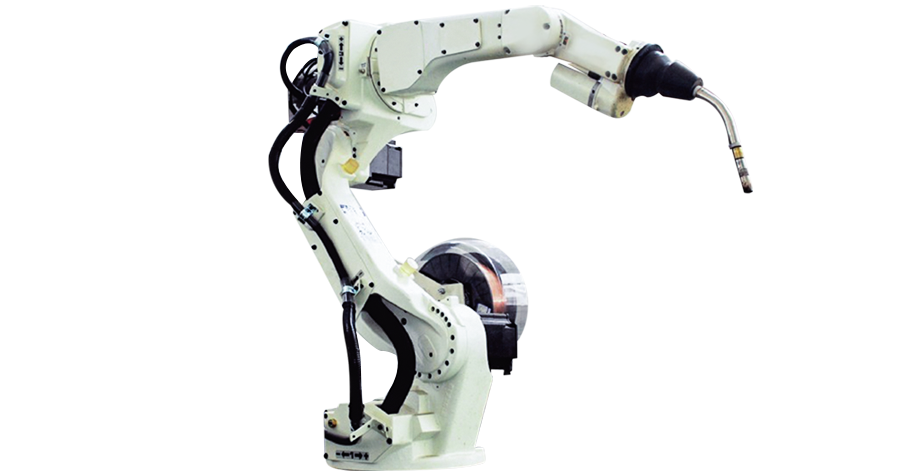

1. Automobile manufacturing: Manipulator components are widely used in the production of automotive parts, such as engine, chassis, body, and other components' production and processing.

2. Electronic products: In the production process of mobile phones, computers, household appliances, and other products, manipulator components can achieve efficient and precise production and processing.

3. Medical equipment: Manipulator components play an important role in the production and processing of medical equipment, such as syringes, surgical instruments, and other component production and processing.

4. Packaging industry: In the production process of food, cosmetics, daily necessities, and other packaging products, manipulator components can achieve fast and accurate production and processing.

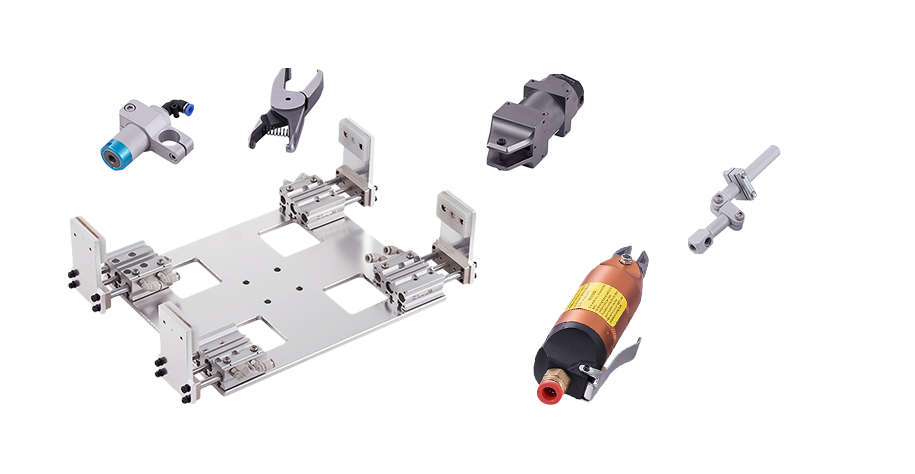

Product Classification:

1. Sensors: Sensors are an important part of manipulators. They can perceive changes in the external environment and transmit signals to the control system to achieve precise control of the manipulator. There are various types of sensors, including photoelectric sensors, pressure sensors, distance sensors, etc.

2. Shearing tools: The shearing tool is a multi-functional and efficient tool used for cutting, trimming or severing metal materials.

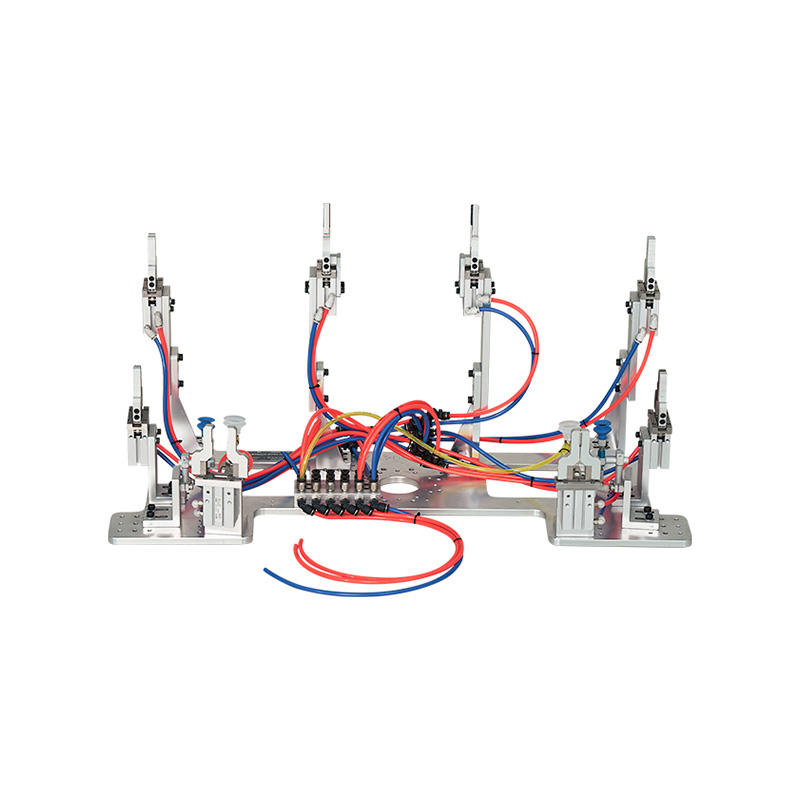

3. Frame series: The frame series is the main structure of the manipulator. Its stability and rigidity directly affect the working performance of the manipulator. The design of the frame series needs to consider factors such as the working range and load capacity of the manipulator.

4. Function clamps: Function clamps are important components for manipulators to perform grasping, handling, and other tasks. Their design and manufacture need to consider factors such as the shape, size, weight, etc. of the workpiece.

5. Quick clamp exchange accessories: Quick clamp exchange accessories can achieve quick replacement of clamps, improving the work efficiency of the manipulator.

6. Piping parts: Piping parts are an important part of the pneumatic system of the manipulator. Their design and manufacture need to consider factors such as pressure and flow rate of the air source.

7. Micro cylinders, rectangular cylinders: Micro cylinders and rectangular cylinders are the power source of manipulators, their performance directly affects the working performance of the manipulator.

8. Suction cups: The suction cup is a device that can firmly adhere to various smooth surfaces through the principle of vacuum adsorption, and it is widely used for lifting, fixing, and suspending items. The design and manufacture of suction cups need to take into account factors such as the size of the adsorption force and stability.

9. Vacuum generator/filter confirmation valve: Vacuum generator/filter confirmation valve is an important part of the vacuum system of the manipulator, its performance directly affects the efficiency of the vacuum system.

10. Fixture accessories: Fixture accessories are important components for manipulators to perform fine operations. Their design and manufacture need to consider factors such as the shape, size, weight, etc. of the workpiece.

Purchasing Considerations:

1.Choose suitable mechanical arm components according to production needs, such as functional clamps, sensors, etc.

2.Choose mechanical arm components with good quality and stability to ensure the stability of the production process and product quality.

3.Consider the maintenance and replacement costs of mechanical arm components and choose components that are easy to maintain and replace.

4.Choose suppliers with good after-sales service and technical support to ensure timely help and support during use.

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى