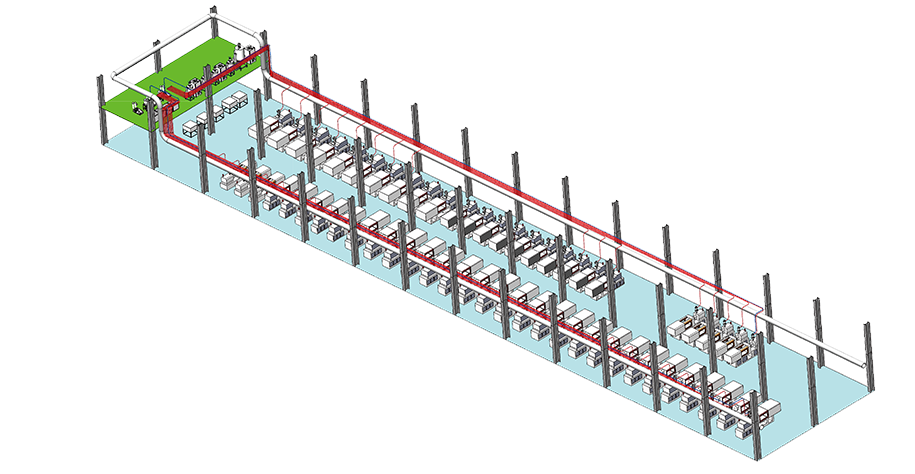

The injection molding machine special manipulator series is an indispensable and important equipment in modern manufacturing industry. They play an important role in improving production efficiency, reducing labor intensity, and ensuring product quality. According to different functions and application fields, the injection molding machine robot series can be divided into three categories: injection molding machine picking robots, injection molding machine film labeling, and injection molding machine insert embedding. The following will elaborate on these three types of injection molding machine robots from four aspects: features, application fields, classification, and purchasing considerations.

Features:

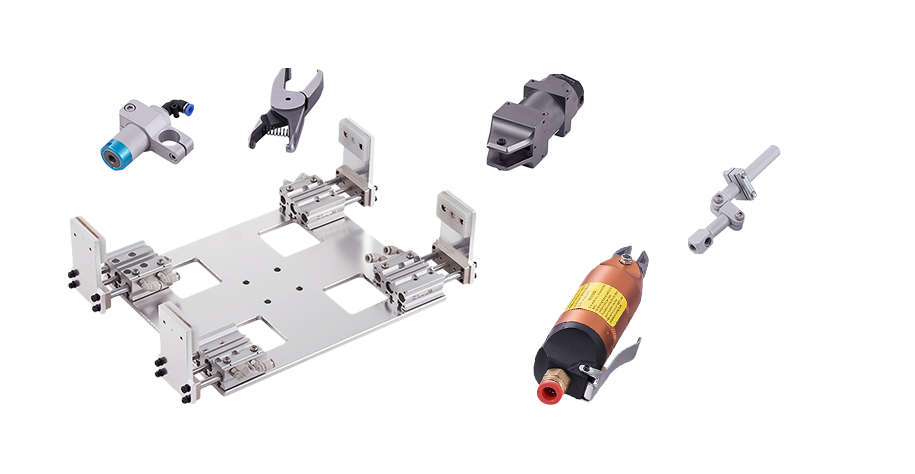

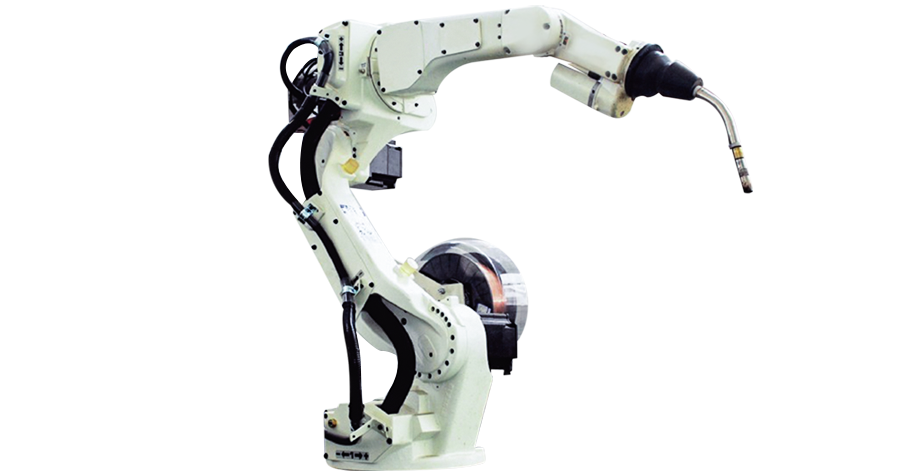

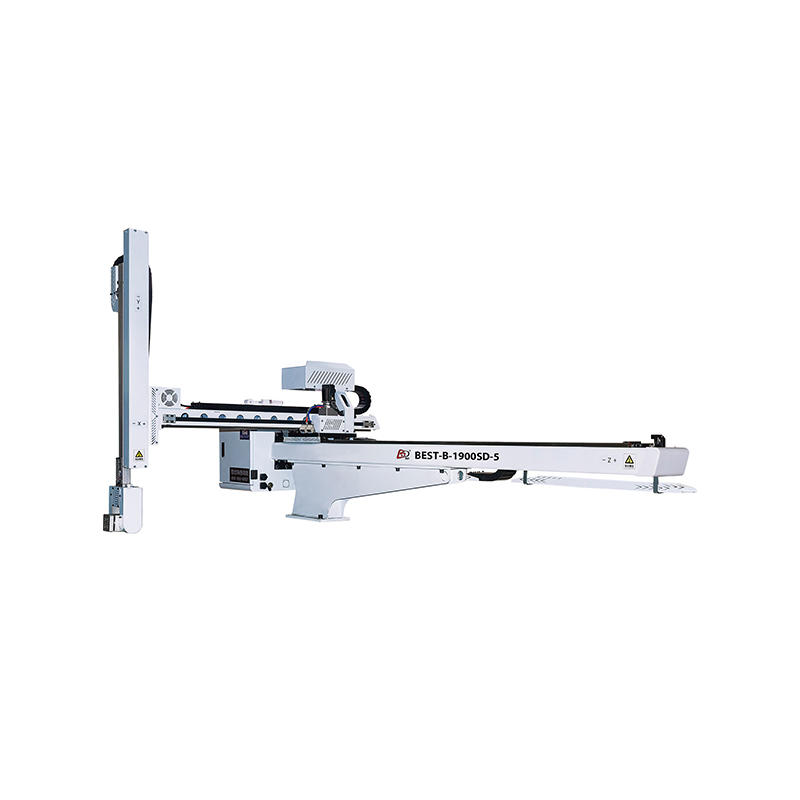

1. Injection molding machine picking robots: This type of robot is mainly used to remove the finished products from the mold after injection molding, with the characteristics of being fast, accurate, and stable. They are usually driven by servo motors and have high repeat positioning accuracy and motion speed, which can meet the needs of high-speed production.

2. Injection molding machine film labeling: This type of robot is mainly used to automatically label or brand the surface or inside of the product during the injection molding process. It has high precision positioning and labeling capabilities, ensuring the accurate position and quality of the label.

3. Injection molding machine insert embedding: This type of robot is mainly used to automatically embed pre-buried inserts into the product after injection molding. It has high-speed and stable embedding capabilities, ensuring the accurate position and reliable quality of the insert.

Application fields:

1. Injection molding machine picking robots: Widely used in automotive, household appliances, electronic products, medical devices, and other industries for automated finished product removal and packaging on injection molding production lines.

2. Injection molding machine film labeling: Mainly used in food, beverage, cosmetics, medicine, and other industries for automatic labeling and identification of products during injection molding production.

3. Injection molding machine insert embedding: Mainly used in automotive, electronics, household appliances, and other industries for automatic insert embedding and assembly during injection molding production.

Classification:

1. Classified by structural form: Injection molding machine picking robots can be divided into single-axis robots and multi-axis robots; Injection molding machine film labeling can be divided into flat labeling robots and rotary labeling robots; Injection molding machine insert embedding can be divided into single-axis insert embedding robots and multi-axis insert embedding robots.

2. Classified by driving mode: Injection molding machine picking robots can be divided into pneumatic robots, hydraulic robots, and electric robots; Injection molding machine film labeling and injection molding machine insert embedding robots generally use electric drive modes.

Purchasing considerations:

1. Choose the appropriate type and specifications of the robot according to actual production needs, including working range, load capacity, motion speed, etc.

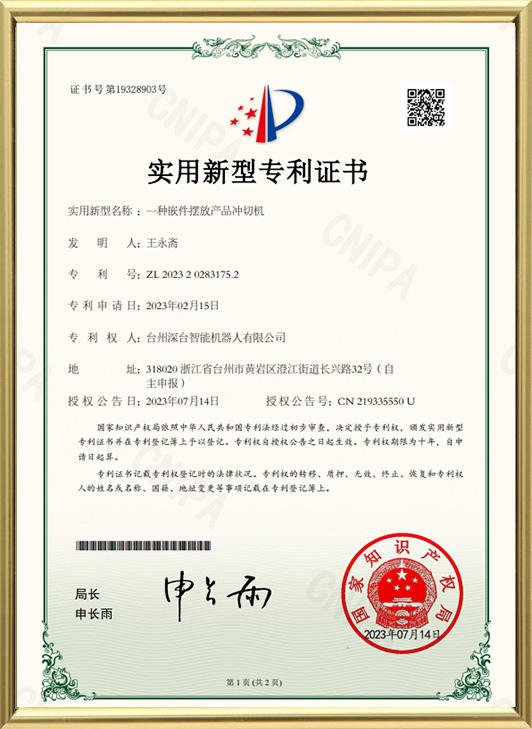

2. Choose a supplier with a high brand reputation and good reputation to ensure the quality of the robot and after-sales service.

3. Consider the installation and maintenance costs of the robot, including equipment price, maintenance costs, training costs, etc.

4. Consider the compatibility and scalability of the robot to ensure smooth use in future production upgrades.

5. Consider the safety performance of the robot, including safety protection devices, emergency stop functions, etc. to ensure the safety of operators.

In conclusion, the injection molding machine special manipulator series has important application value in modern manufacturing industry. According to different functions and application fields, it can be divided into three categories: injection molding machine picking robots, injection molding machine film labeling, and injection molding machine insert embedding. When purchasing an injection molding machine robot, it is necessary to choose the appropriate type and specifications according to actual production needs, consider factors such as supplier's brand reputation, after-sales service, installation and maintenance costs, compatibility and scalability, and safety performance.

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى