Industrial robots are machine devices that can automatically perform tasks, capable of replacing humans in completing repetitive, dangerous, and high-precision work. With the continuous development of technology, industrial robots have been widely applied in various fields. This article will provide a detailed description of industrial robots from four aspects: features, application areas, classification, and purchasing considerations.

Features:

1. Efficient: Industrial robots have high work efficiency, able to complete a large number of tasks in a short time and improve production efficiency.

2. Precise: Industrial robots have high positioning accuracy and repeat positioning accuracy, capable of meeting the needs of high-precision operations.

3. Stable: Industrial robots have strong anti-interference capabilities, able to work stably in harsh environments.

4. Safe: Industrial robots can work in high-temperature, high-pressure, toxic, and other dangerous environments, avoiding personnel casualty accidents.

5. Flexible: Industrial robots have strong adaptability, able to be programmed and adjusted according to different production tasks.

Application Areas:

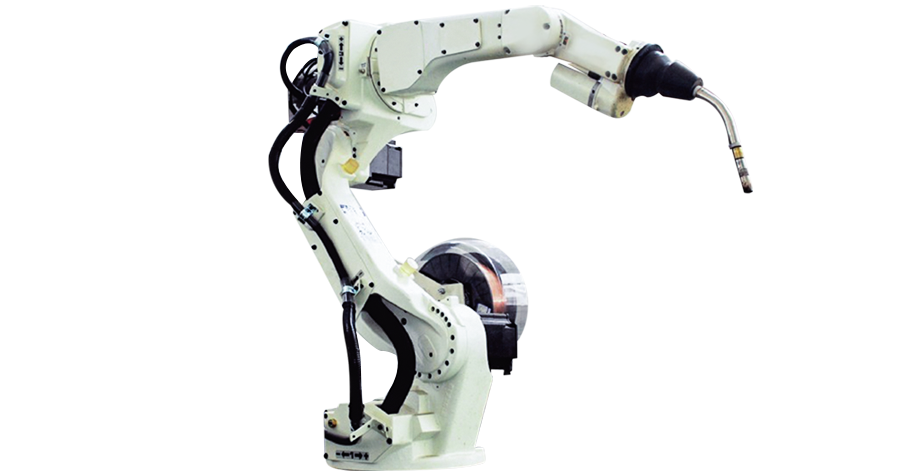

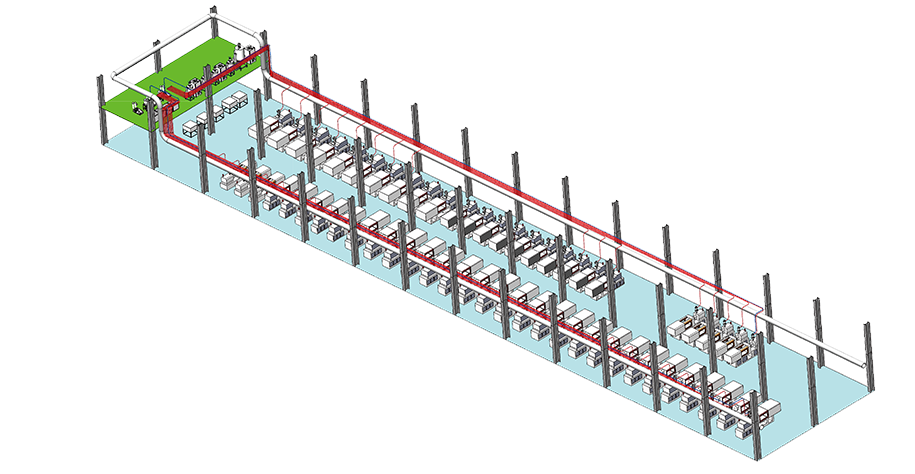

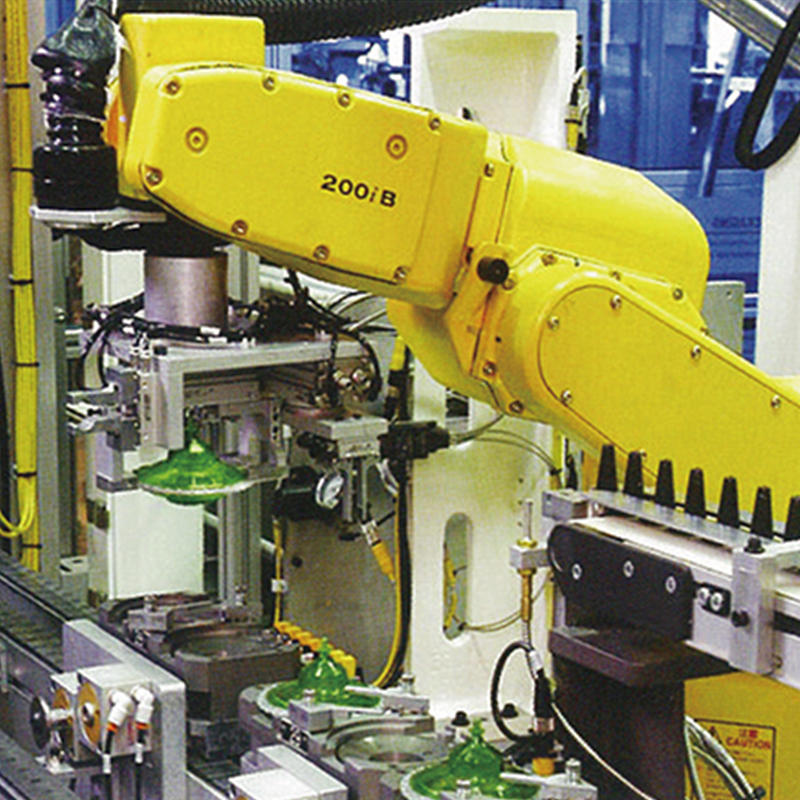

1. Frame robot welding unit: Widely used in automotive manufacturing, shipbuilding, steel structure, and other fields for welding frames, hulls, and other large structural components.

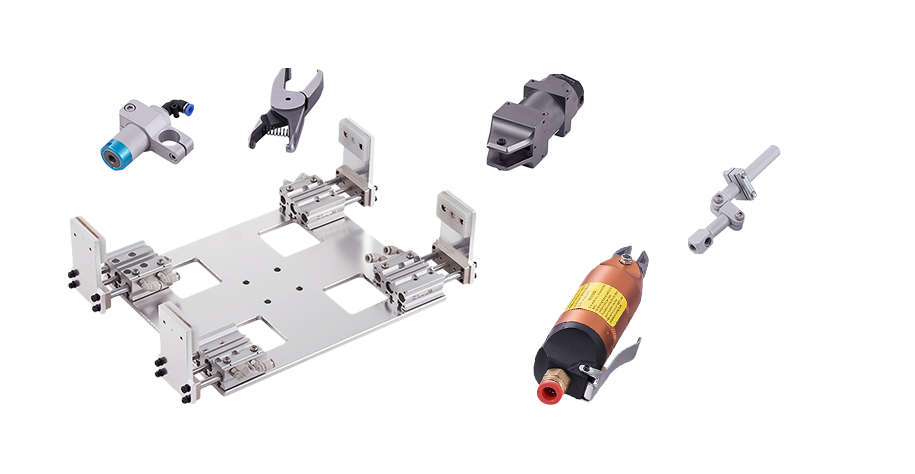

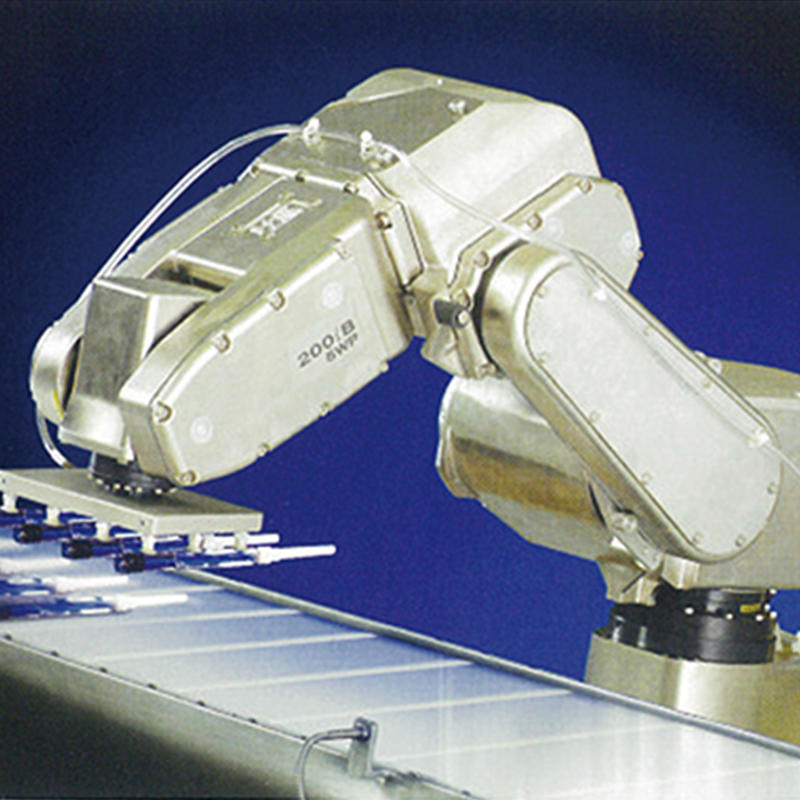

2. Online grasping robot unit: Widely used in logistics, warehousing, food processing, and other fields for automatic sorting, handling, packaging, and other tasks.

3. Food palletizing robot unit: Widely used in food processing, beverage production, and other fields for automatic palletizing and boxing of finished products.

4. Online visual inspection robot unit: Widely used in electronics, semiconductors, precision manufacturing, and other fields for automatic inspection and screening of products.

Classification:

According to structure and function, industrial robots can be classified into four categories: frame robot welding units, online grasping robot units, food palletizing robot units, and online visual inspection robot units.

Purchasing Considerations:

1. Choose the appropriate type of industrial robot based on actual needs, such as frame robot welding units being suitable for large structural component welding while online grasping robot units are suitable for logistics and warehousing.

2. Consider the load capacity of the industrial robot to ensure it meets the requirements of the production task.

3. Choose an industrial robot with high positioning accuracy and repeat positioning accuracy to meet the needs of high-precision operations.

4. Consider the working environment of the industrial robot and choose one suitable for special environments, such as high temperature resistance, high pressure resistance, corrosion resistance, etc.

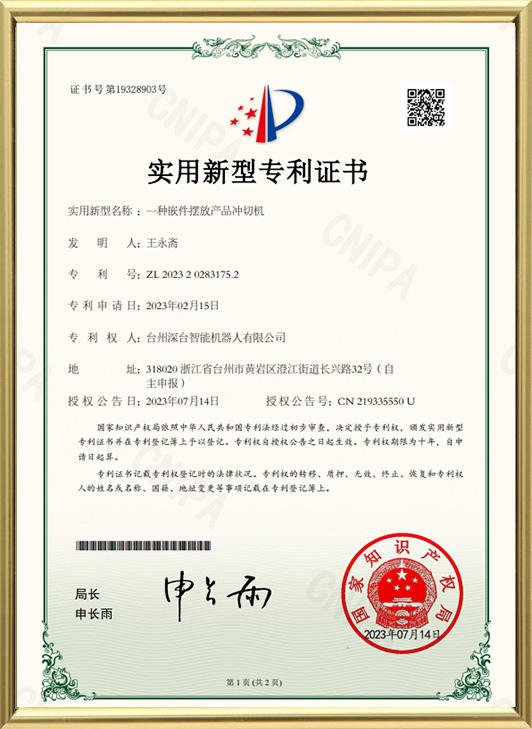

5. Choose an industrial robot brand with good after-sales service and technical support to ensure timely maintenance and repair during use.

6. During the purchasing process, consult professionals or refer to industry experience to better understand the performance and scope of application of industrial robots.

In summary, industrial robots play an increasingly important role in modern industrial production. They have efficient, precise, stable, safe, and flexible characteristics and are widely used in various fields. When purchasing industrial robots, it is necessary to select the appropriate type and performance parameters based on actual needs, pay attention to after-sales service and technical support to ensure that industrial robots can create greater value for enterprises.

View More

View More

View More

View More

View More

View More

View More

View More

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى