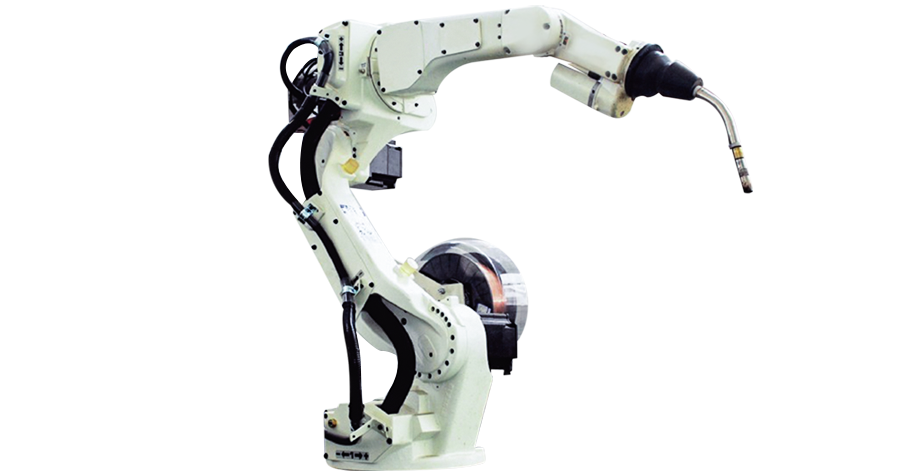

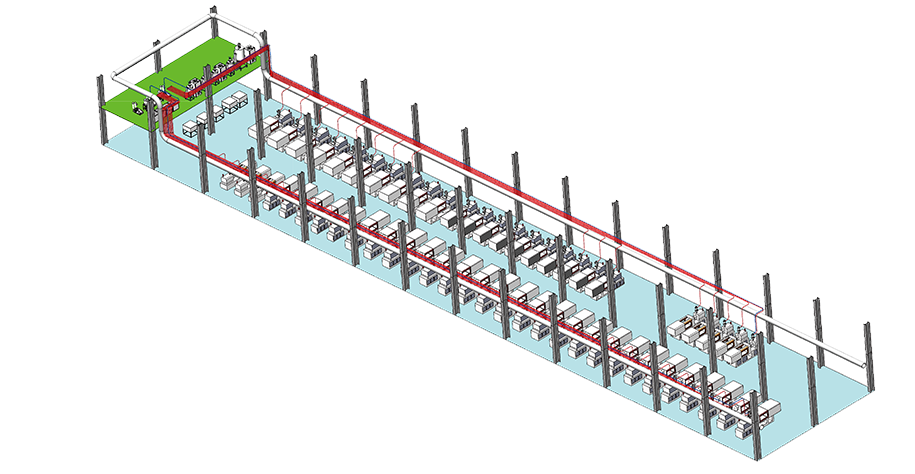

Injection molding machine part removal robot is a kind of equipment used in the automated production line, mainly used to take out the molded parts from the injection molding machine and place them in designated positions. It can improve production efficiency, reduce labor costs, and have high precision and stability. The following will describe the injection molding machine part removal robot in detail from four aspects: characteristics, application fields, classification, and selection considerations.

Features:

1. Automatic operation: The injection molding machine part removal robot can automatically complete the part removal and placement actions according to the preset program, without manual intervention, greatly improving production efficiency.

2. High precision positioning: The injection molding machine part removal robot uses advanced positioning systems to accurately control the position and posture of the arms, ensuring the accuracy and stability of part removal.

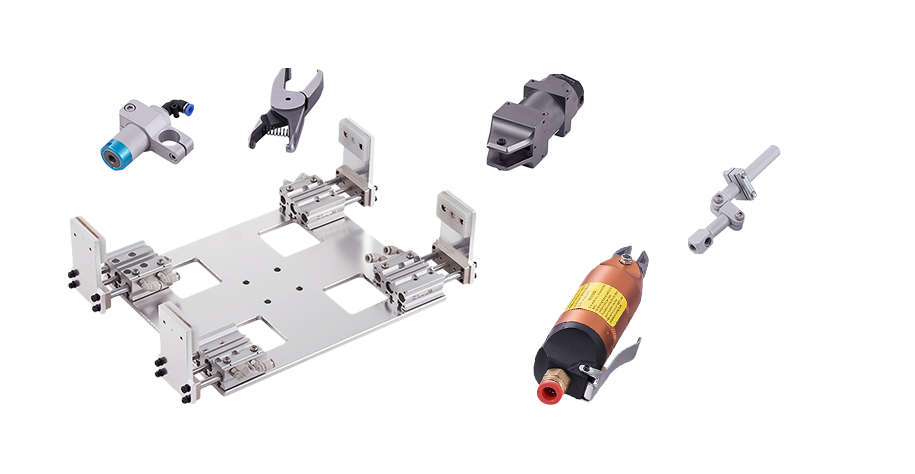

3. Flexible adaptation: The injection molding machine part removal robot can adjust and adapt to different product shapes and sizes, meeting different production requirements.

4. Safe and reliable: The injection molding machine part removal robot uses multiple safety protection measures, such as collision detection, emergency stop, to ensure safety during operation.

Application Fields:

1. Automotive industry: Injection molding machine part removal robots are widely used in the production of automotive parts, such as door panels, roof panels, instrument panels, etc.

2. Electronics and electrical industry: Injection molding machine part removal robots play an important role in the manufacturing process of electronic products, such as mobile phone cases, computer accessories, etc. Part removal and assembly.

3. Medical device industry: Injection molding machine part removal robots are widely used in the production process of medical devices, such as syringes, surgical instruments, etc. Part removal and packaging.

4. Plastic products industry: Injection molding machine part removal robots play a crucial role in the production process of plastic products, such as plastic containers, plastic parts, etc. Part removal and packaging.

Classification:

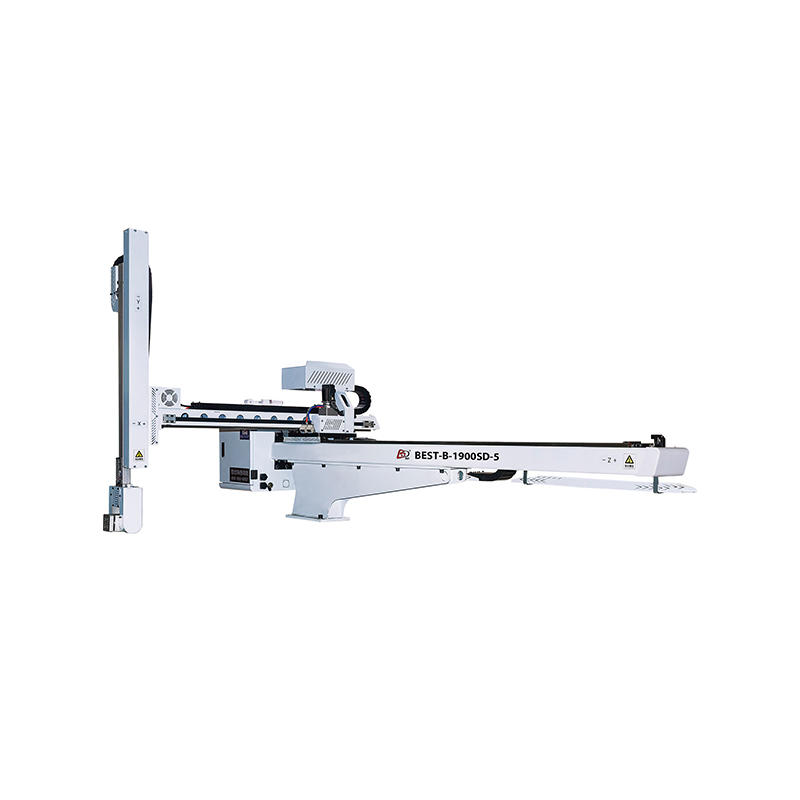

1. Three-axis traverse single-arm single-section: This type of robot has a traverse three-axis arm that can perform single grasping and placement actions. It is suitable for some simple part removal and placement tasks.

2. Three-axis traverse single-arm double-section: Compared to the single-section type, this robot has two limbs that can simultaneously perform two grasping and placement actions, improving production efficiency.

3. Three-axis bullhead single-arm double-section: This type of robot has a head structure similar to a bullhead, which can perform complex grasping and placement actions. It is suitable for some specially shaped products.

4. Three-axis vertical traverse single-arm double-section: Compared to the traverse type, this robot has a vertical traverse three-axis arm that can perform longitudinal grasping and placement actions. It is suitable for some tasks that require longitudinal movement.

5. Five-axis traverse double-arm single-section: This type of robot has two traverse five-axis arms that can perform more complex grasping and placement actions. It is suitable for the production of some large products.

6. Five-axis traverse double-arm double-section: Compared to the single-section type, this robot has two limbs that can simultaneously perform two grasping and placement actions, further improving production efficiency.

7. Five-axis bullhead single-arm double-section: Compared to the three-axis bullhead type, this robot has five axes of movement ability, which can perform more flexible and precise grasping and placement actions.

8. Oblique arm machine: This type of robot has an inclined arm structure that can perform oblique grasping and placement actions. It is suitable for some products with special angles.

In summary, the injection molding machine part removal robot is an efficient, precise, and stable automated equipment that is widely used in the automotive manufacturing, electronics and electrical, medical devices, and plastic products industries. Different types of injection molding machine part removal robots can be selected according to different production requirements and product characteristics. When selecting, factors such as accuracy, stability, safety performance, and maintenance should be considered to ensure that suitable equipment is selected.

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى