Robotic arm welding machines are sophisticated automation systems designed to perform welding operations with precision and efficiency. These machines feature articulated robotic arms equipped with welding torches, sensors, and advanced control systems. Robotic arm welding machines offer numerous advantages over traditional manual welding methods.

Precision: Robotic arms execute welds with high precision, ensuring consistent quality and accuracy in weld seams.

Efficiency: Automated welding processes reduce cycle times and increase productivity, allowing for higher throughput and lower production costs.

Flexibility: Robotic arm welding machines can adapt to various welding tasks, including arc welding, MIG welding, TIG welding, and spot welding, across different materials and geometries.

Safety: By replacing human operators in hazardous welding environments, robotic arm welding machines enhance workplace safety and reduce the risk of injuries.

Robotic arm welding machines incorporate several key features and technologies to optimize welding performance and efficiency, including:

Advanced Control Systems: Precision control algorithms and motion planning techniques enable robotic arms to execute complex welding paths with small deviation.

Vision Systems: Integrated vision systems provide real-time feedback and inspection capabilities, allowing robots to adjust welding parameters and adapt to variations in workpieces.

Collaborative Functionality: Some robotic arm welding machines feature collaborative capabilities, allowing human operators to work alongside robots safely and efficiently.

Offline Programming: Offline programming software enables users to simulate and optimize welding processes offline, reducing setup times and increasing productivity.

Robotic arm welding machines find applications across various industries and sectors, including automotive manufacturing, aerospace, shipbuilding, and construction. Key applications include:

Automotive Industry: Robotic arm welding machines automate the assembly of vehicle chassis, body panels, and structural components, ensuring precise welds and high-quality finishes.

Aerospace Manufacturing: Robotic welding systems are used to fabricate aircraft structures, engine components, and fuselage assemblies with stringent quality and performance requirements.

Shipbuilding and Marine Engineering: Robotic arm welding machines streamline the construction of ships, offshore platforms, and marine structures, improving efficiency and reducing production lead times.

Infrastructure and Construction: Robotic welding technology is increasingly used in construction projects, such as bridge fabrication, pipeline welding, and structural steel fabrication, to enhance productivity and quality.

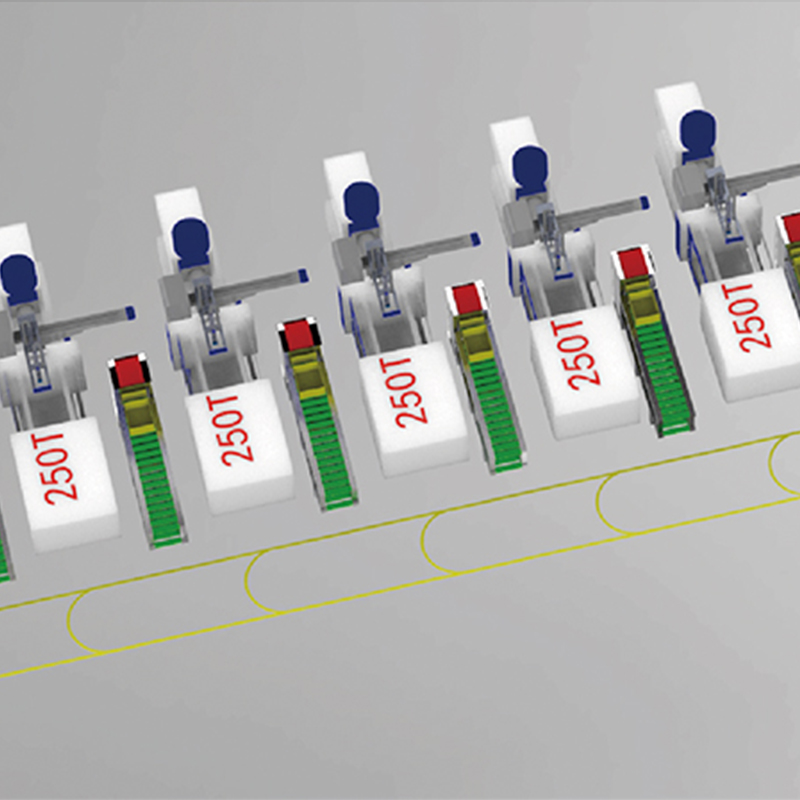

Hydraulic robot arms represent a versatile and powerful class of industrial robots driven by hydraulic actuators. These robot arms offer high payload capacities, robustness, and flexibility, making them suitable for heavy-duty applications in manufacturing, construction, and material handling.

High Payload Capacity: Hydraulic robot arms can lift and manipulate heavy loads, making them ideal for tasks such as material handling, assembly, and construction.

Durability: Hydraulic actuators provide robust and reliable performance in demanding industrial environments, including bad temperatures, dust, and vibration.

Flexibility: Hydraulic robot arms can be configured with various end-effectors and tooling options to perform a wide range of tasks, from palletizing and welding to demolition and excavation.

Remote Operation: Some hydraulic robot arms are designed for remote operation in hazardous or inaccessible environments, such as nuclear facilities, offshore platforms, and disaster zones.

Hydraulic robot arms find applications in diverse industries and sectors, including manufacturing, construction, agriculture, and mining.

Material Handling: Hydraulic robot arms are used for loading and unloading heavy materials, palletizing, and sorting in warehouses, distribution centers, and manufacturing facilities.

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى