The manufacturing industry has always been at the forefront of innovation, constantly seeking ways to enhance efficiency, speed, and reliability. One of the key technologies driving this evolution is the Gantry Robotics system.

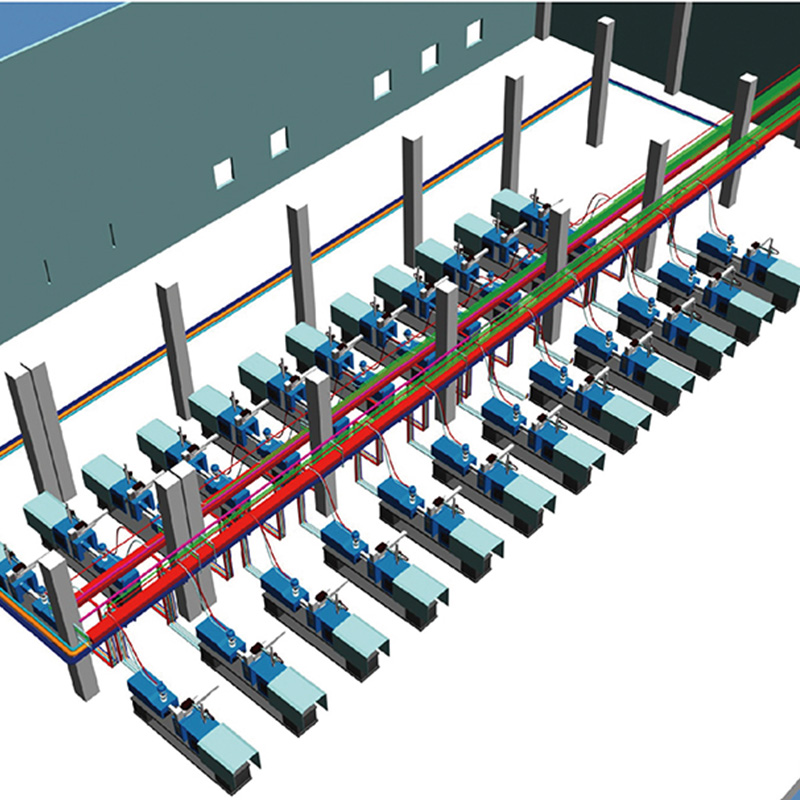

A Gantry Palletizer System is a type of robotic system specifically designed for the automated loading and unloading of pallets in warehouses and manufacturing facilities. This system utilizes a gantry type robot, which is a robot mounted on an overhead structure (gantry), to pick up and place products or materials onto pallets with precision and speed.

The Gantry Palletizer System offers several advantages:

Increased Efficiency: With automated palletizing, the system can handle large volumes of products or materials quickly and consistently.

Space Optimization: The overhead gantry design allows for efficient use of floor space, making it ideal for facilities with limited space.

Flexibility: The system can be easily programmed to handle a variety of products or materials, making it versatile for different manufacturing needs.

Gantry Type Robot: A Flexible Solution

A Gantry Type Robot refers to a robot that is mounted on a gantry structure, allowing it to move horizontally along tracks while also having vertical movement capabilities. This design offers increased reach and flexibility compared to traditional robotic arms, making it suitable for a wide range of applications.

Some key features and benefits of Gantry Type Robots include:

High Payload Capacity: Gantry robots can handle heavy loads, making them suitable for handling large products or materials.

Extended Reach: The overhead gantry design allows the robot to access a larger workspace, enabling it to handle products or materials across a broader area.

Precision and Accuracy: With advanced motion control systems, gantry robots can achieve high levels of precision and accuracy, ensuring consistent performance.

The Pick and Place Gantry Robot is a specialized gantry robot designed for automated picking and placing of objects or components in manufacturing processes. This robot is equipped with grippers or suction cups to pick up items from one location and place them at another with precision.

Key benefits of Pick and Place Gantry Robots include:

Speed: These robots can pick and place items at high speeds, increasing throughput and productivity.

Consistency: Automated picking and placing ensure consistent positioning and alignment of items, reducing errors and waste.

Safety: By automating repetitive tasks, pick and place robots can reduce the risk of injuries associated with manual handling.

Applications of Gantry Robotics

Gantry Robotics finds applications across various industries and manufacturing processes:

Palletizing: In warehouses and distribution centers, Gantry Palletizer Systems are used to automate the stacking of products onto pallets.

Assembly: Gantry Type Robots are employed in assembly lines to handle and position components for product assembly.

Packaging: Pick and Place Gantry Robots are used in packaging lines to pick up products and place them into containers or boxes.

Material Handling: Gantry robots can be used for transporting materials between different stages of the manufacturing process, optimizing workflow and reducing manual labor.

While Gantry Robotics offers numerous benefits, there are challenges to consider, such as initial setup costs, integration with existing systems, and the need for specialized training for operators. However, as technology continues to advance, these challenges are becoming more manageable.

Gantry Robotics has become a cornerstone technology in modern manufacturing, offering versatile solutions for palletizing, assembly, packaging, and material handling. With their flexibility, speed, and precision, Gantry Type Robots and Pick and Place Gantry Robots are reshaping the way industries approach automation. While challenges exist, the benefits of gantry robotics far outweigh the drawbacks, making them a valuable investment for forward-thinking manufacturers.

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى