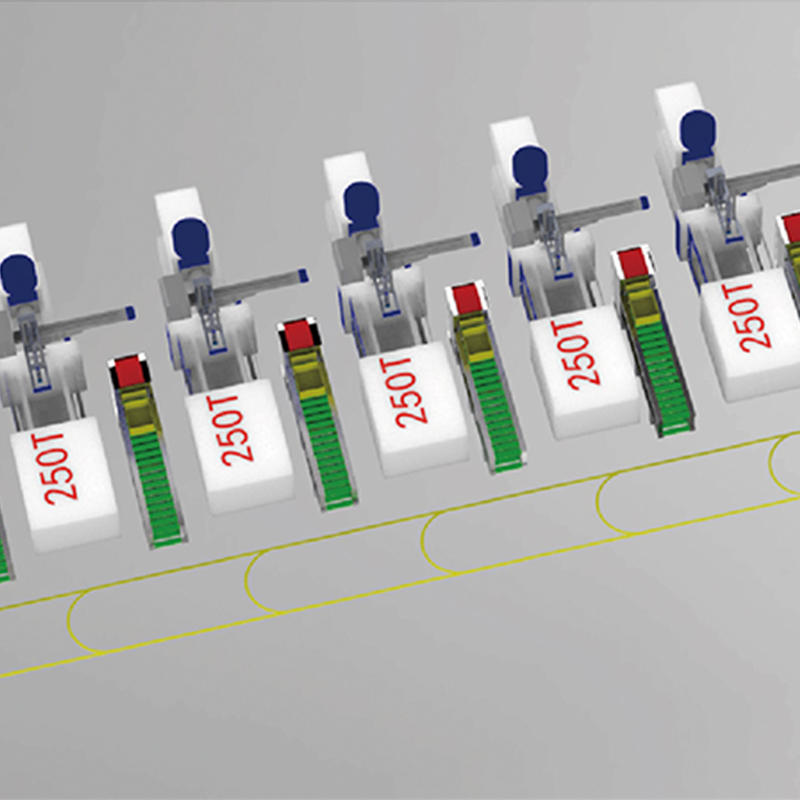

Product Features:

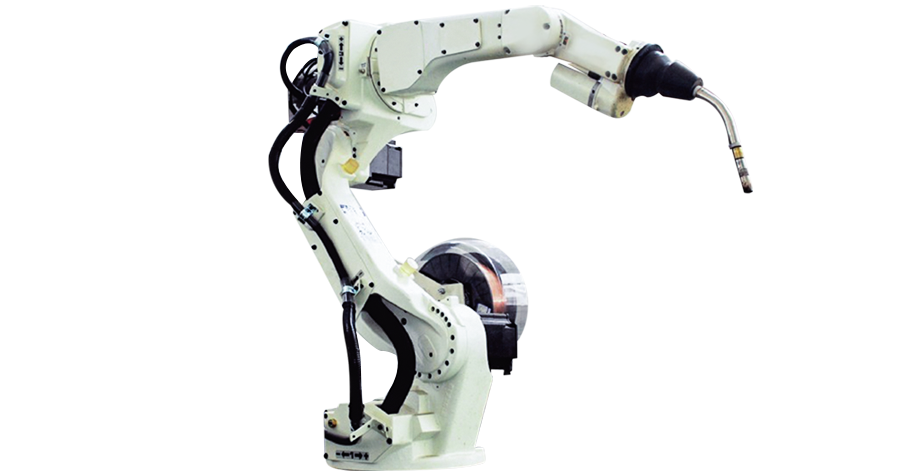

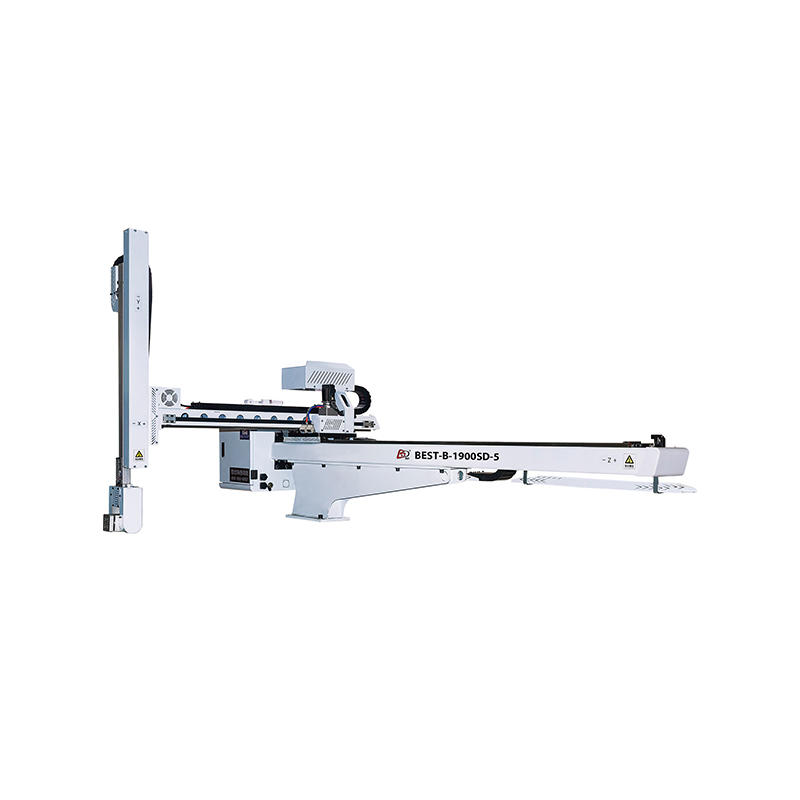

1. High Precision Sensing: The injection molding machine dedicated robot sensor uses advanced sensing technology to accurately perceive the position, shape, and size of objects, achieving precise control of the injection molding machine.

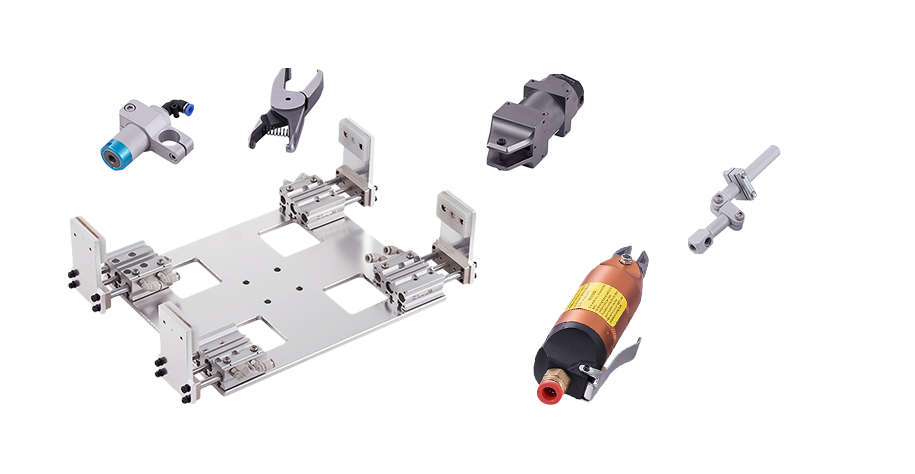

2. Multi-functionality: The sensor has multiple functions, including position detection, pressure detection, temperature detection, etc., meeting the needs of different injection molding machines.

3. Fast Response: The sensor has a fast response speed, can monitor the working status of the injection molding machine in real-time, and adjust the movements of the robotic arm promptly, improving production efficiency.

4. Strong Anti-interference Capability: The sensor uses special design and materials to effectively resist external electromagnetic interference and vibration interference, ensuring stability and reliability of operation.

5. Easy Installation and Maintenance: The sensor adopts modular design, making installation easy and maintenance simple. Users can replace and repair it as needed.

Product Advantages:

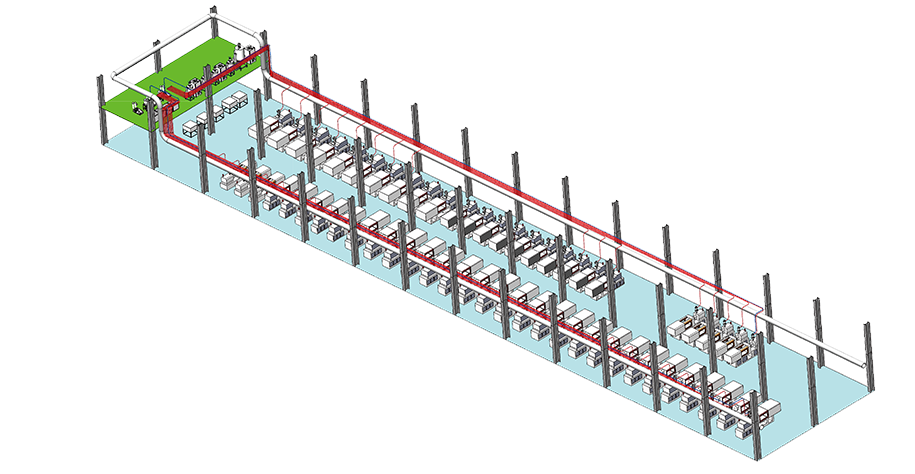

1. Improve Production Efficiency: The injection molding machine dedicated robot sensor can monitor the working status of the injection molding machine in real-time, adjust the movements of the robotic arm according to needs, reduce manual intervention, and improve production efficiency.

2. Reduce Production Costs: The high precision sensing and fast response capabilities of the sensor can reduce misoperations and waste rates, thereby reducing production costs.

3. Improve Product Quality: The sensor can accurately perceive the position, shape, and size of objects, ensuring the quality and consistency of injection-molded products, enhancing product competitiveness.

4. Enhance Working Environment: The strong anti-interference capability of the sensor can reduce the impact of electromagnetic interference and vibration interference on the working environment, improving comfort and safety.

5. Extend Equipment Lifespan: The high precision sensing and fast response capabilities of the sensor can reduce wear and damage to the robotic arm, extending the service life of the equipment.

6. Simplify Operation Process: The multi-functionality and easy installation and maintenance characteristics of the sensor can simplify the operation process, reducing the workload of operators.

7. Provide Data Analysis: The sensor can monitor the working status of the injection molding machine in real-time, providing accurate data for analysis and optimization, helping users improve production processes and product quality.

8. Adapt to Diverse Needs: The sensor has multiple functions and can meet the needs of different injection molding machines, adapting to diverse production environments and process requirements.

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى