Product Features:

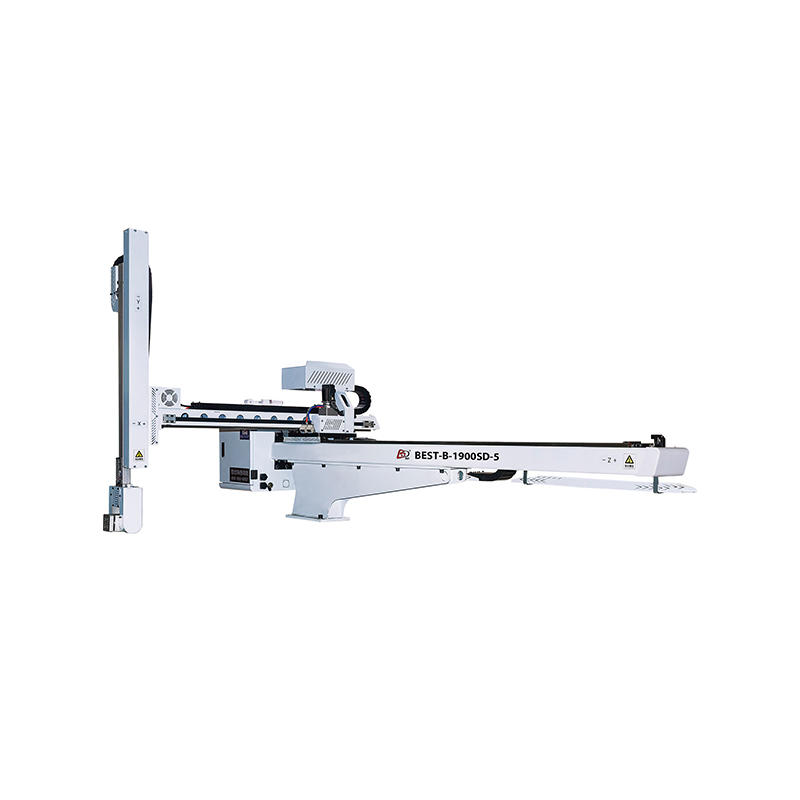

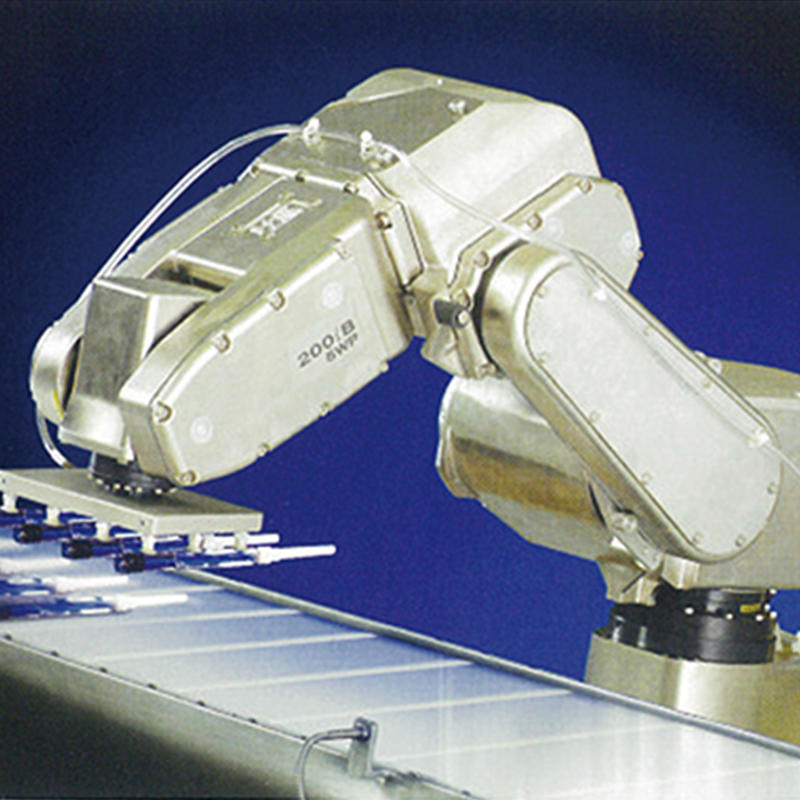

1. Three-axis servomotor drive: This robotic arm adopts advanced three-axis servomotor as the driving device, featuring high precision, high speed, and high stability. Through the servo control system, it can achieve precise position control and motion trajectory planning, meeting various complex operation requirements.

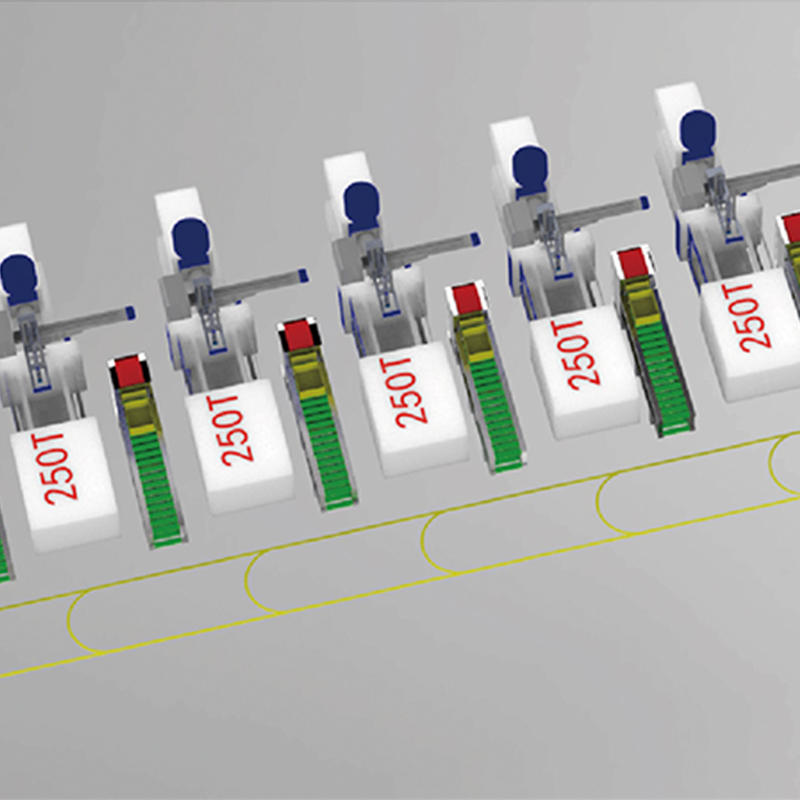

2. Longitudinal structure: Compared to traditional traverse robotic arms, the longitudinal structure makes the robotic arm operate more smoothly during the working process, reducing vibration and noise. At the same time, the longitudinal structure can also provide a larger working space, facilitating operators for maintenance and adjustment.

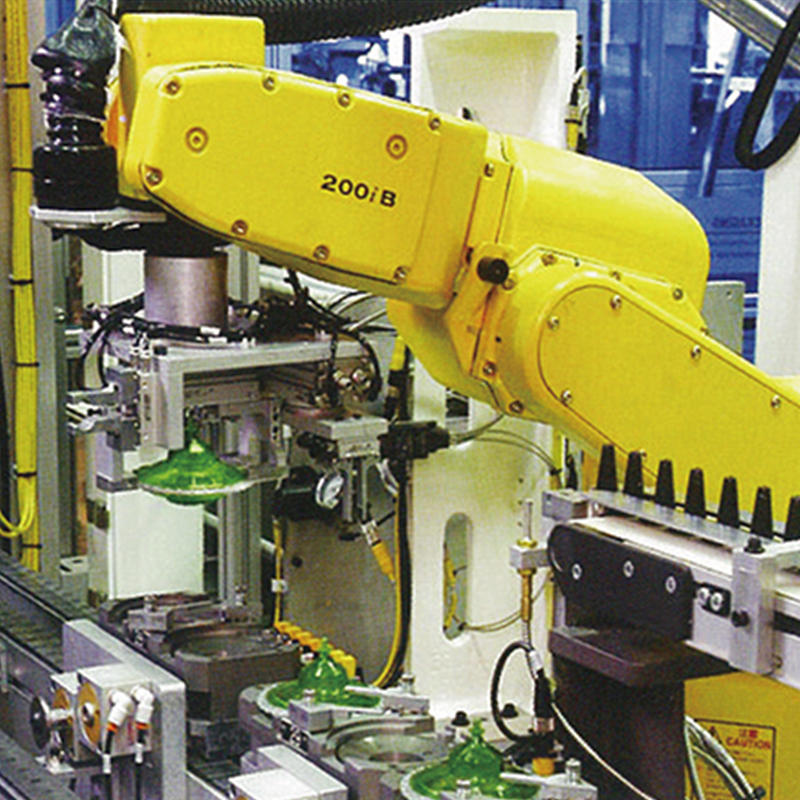

3. Single-arm dual-section design: The robotic arm adopts a single-arm dual-section design, making it more flexible in grasping and placing objects. The dual-section structure can perform independent actions separately, improving work efficiency and operational accuracy.

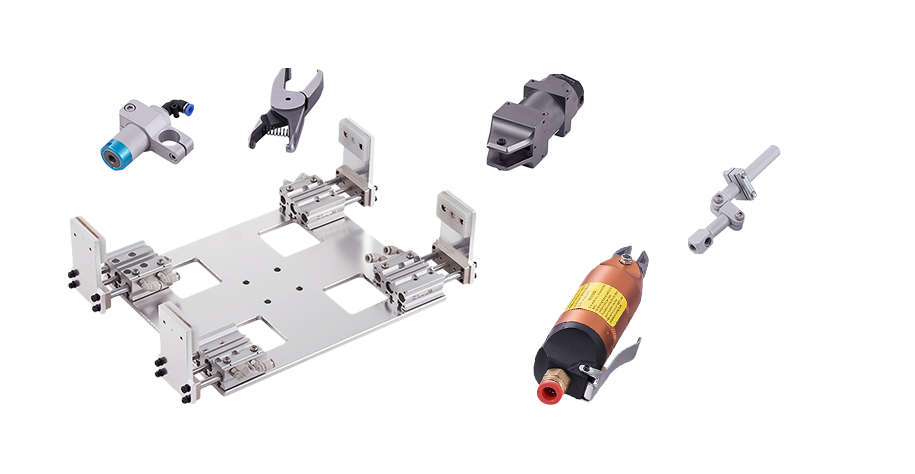

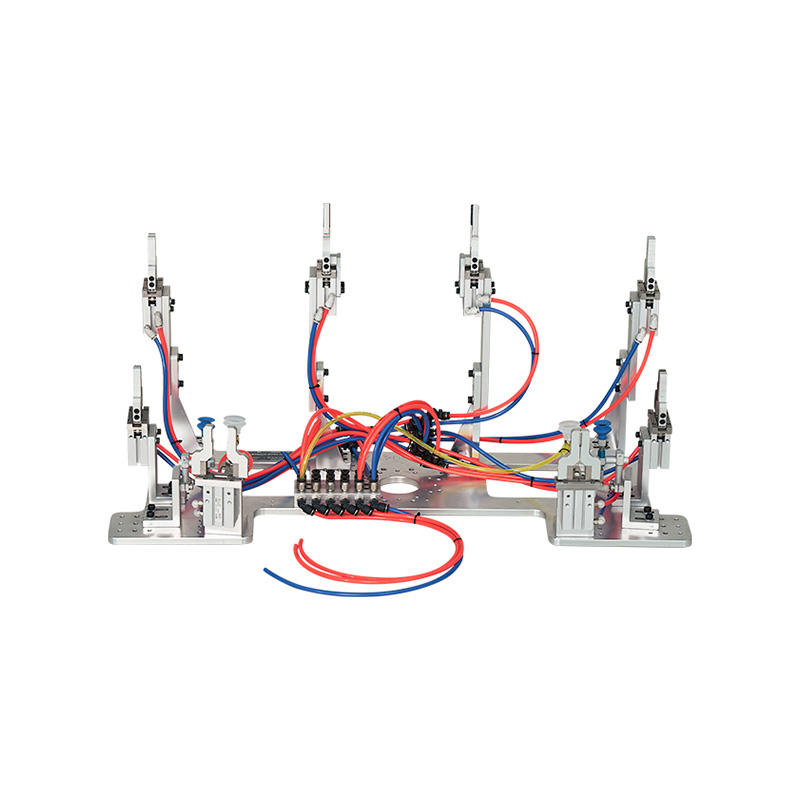

4. Multiple gripper adaptability: The robotic arm is equipped with multiple grippers that can be replaced according to different work requirements. Whether it is suction cups, grippers, or magnetic grippers, they can all well cooperate with the robotic arm to achieve the grasping and placement of various objects with different shapes and materials.

5. Programmable control: The robotic arm is equipped with a programmable controller, allowing for control and operation through programming. Users can write corresponding programs according to actual needs, achieving automated production and operation processes.

Product Advantages:

1. High precision positioning: The high precision control capability of the three-axis servomotor enables the robotic arm to achieve precise position control and motion trajectory planning. Whether it is grasping or placing objects, it can accurately complete the task, ensuring product quality and production efficiency.

2. High-speed movement: The high-speed characteristic of the servomotor allows the robotic arm to quickly perform grasping and placing operations. Compared to traditional pneumatic or hydraulic driving methods, the movement speed of the servomotor is much faster, greatly improving work efficiency.

3. Stable operation: The high stability of the servomotor enables the robotic arm to maintain stable operation during the working process. Whether it is continuous operation for a long time or frequent start-stop operations, the robotic arm can maintain stable performance, reducing the risk of failure and downtime.

4. High flexibility: The single-arm dual-section design makes the robotic arm more flexible in grasping and placing objects. The dual-section structure can perform independent actions separately, allowing for flexible adjustments and operations according to actual needs.

5. Wide adaptability: The robotic arm is equipped with multiple grippers, enabling adaptation to the grasping and placement of objects with different shapes and materials. Whether it is metal, plastic, glass, or other materials, it can achieve corresponding operations by changing the gripper.

6. Programmable control: The provision of a programmable controller enables the robotic arm to achieve automated production and operation processes. Users can write corresponding programs according to actual needs, achieving automated operation and control, improving production efficiency and operational accuracy.

7. Easy maintenance: The design of the longitudinal structure makes the robotic arm operate more smoothly during the working process, reducing vibration and noise. At the same time, the longitudinal structure can also provide a larger working space, facilitating operators for maintenance and adjustment.

8. Safety and reliability: The robotic arm adopts advanced safety protection devices such as collision sensors, overload protection, etc., ensuring operator safety. At the same time, the movement speed and force of the robotic arm are precisely controlled and adjusted, avoiding risks of misoperation and damage to objects.

In conclusion, the three-axis servomotor longitudinal single-arm dual-section robotic arm has high precision, high speed, high stability, high flexibility, wide adaptability, programmable control, easy maintenance, safety, and reliability features and advantages. It can meet various complex operation requirements, improve production efficiency and product quality, and is an indispensable important equipment in modern manufacturing industry.

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى