Product Features:

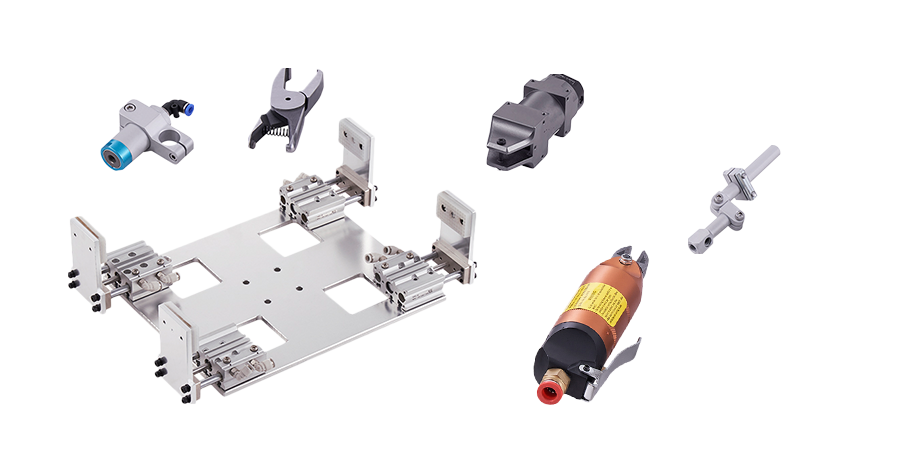

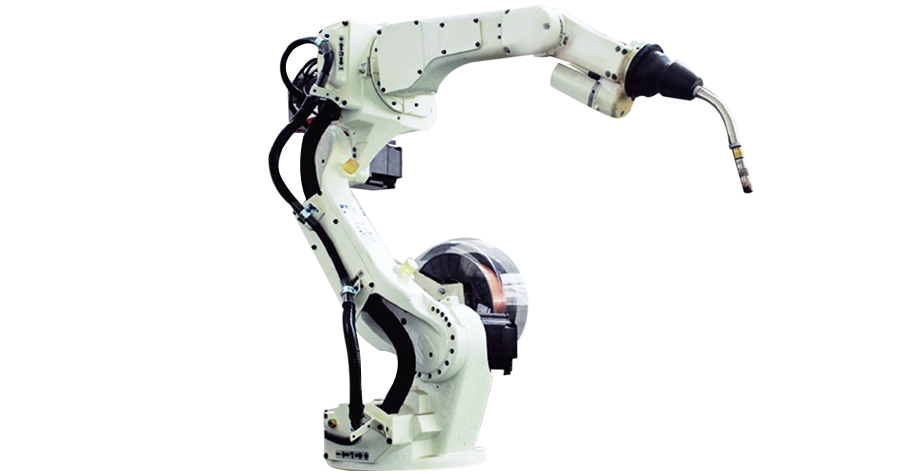

1. Five-axis servo drive: This manipulator adopts advanced five-axis servo drive technology, featuring high precision, high speed, and high stability. Through precise servo control, it can achieve complex motion trajectories and accurate operations.

2. Lateral movement structure: Compared to traditional straight-line manipulators, the lateral movement structure allows the manipulator to move freely in the horizontal plane, providing a larger working range and flexibility.

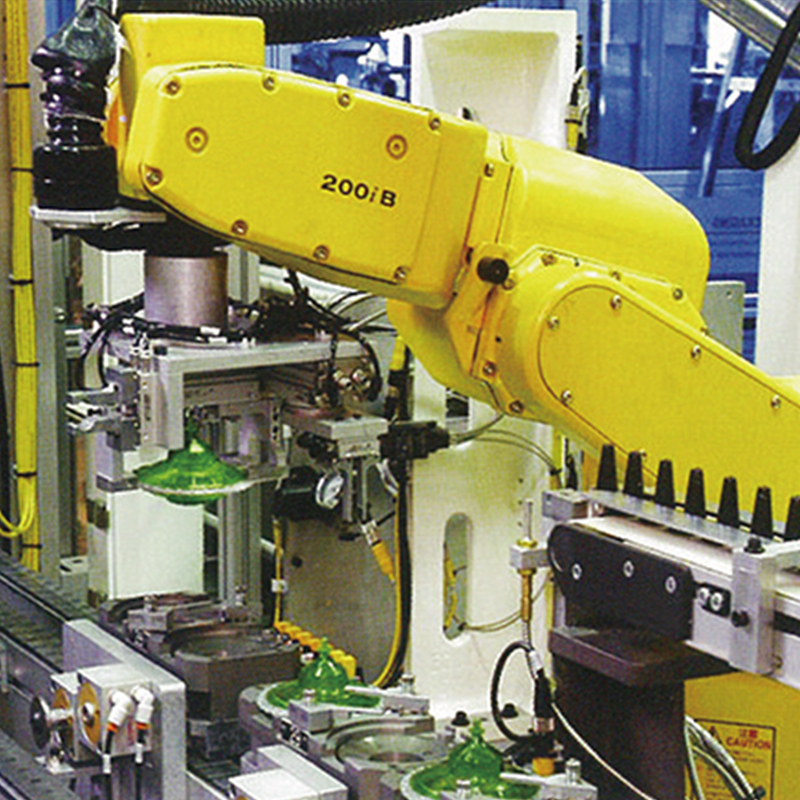

3. Dual-arm design: The manipulator adopts a dual-arm design, with each arm capable of independent operation. It can handle two workpieces simultaneously, improving work efficiency.

4. Two-section structure: Each arm of the manipulator is divided into two sections, enabling more flexible movements and operations. Each section can independently rotate and extend/retract, adapting to workpieces of different shapes and sizes.

5. Programmable control: The manipulator is equipped with a programmable controller, allowing for programming and adjustment according to actual needs, achieving automated production and flexible operations.

Product Advantages:

1. High precision operation: The five-axis servo drive technology enables the manipulator to have high precision operation capabilities, achieving micron-level precision control and meeting the demands of precision machining and assembly.

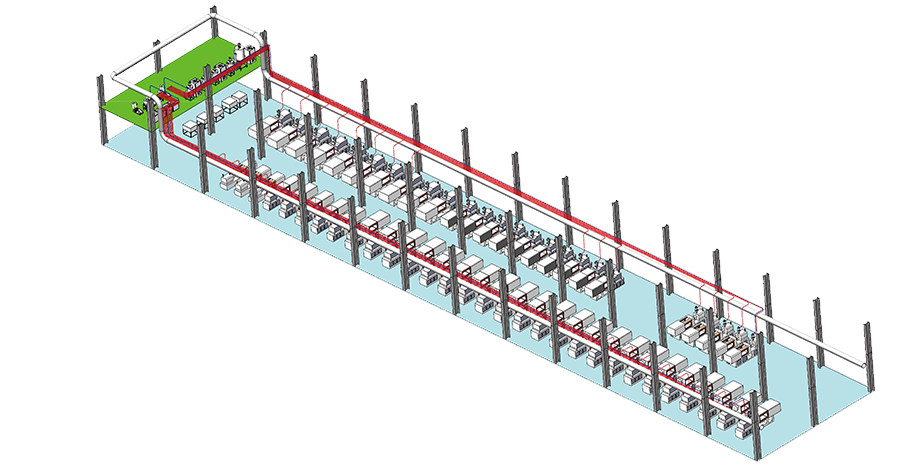

2. Efficient production: The dual-arm design and two-section structure enable the manipulator to handle multiple workpieces simultaneously, greatly improving production efficiency and saving labor and time costs.

3. Strong flexibility: The lateral movement structure and two-section design provide the manipulator with a larger working range and flexibility, adapting to workpieces of different shapes and sizes and meeting diverse production needs.

4. High stability and reliability: Adopting advanced servo control system and precise transmission devices, the manipulator possesses high stability and reliability, ensuring continuous and stable production without frequent failures.

5. Easy programming and adjustment: The programmable controller makes programming and adjusting the manipulator simple and convenient, eliminating the need for specialized technical personnel to complete programming and adjustment tasks.

6. Improved safety: The automation of the manipulator reduces the risks associated with manual operations, enhancing workplace safety.

7. Reduced labor intensity: The automation of the manipulator reduces worker fatigue, improves work efficiency, and minimizes human errors.

8. Cost savings: The efficiency and stability of the manipulator reduce production costs, improve production efficiency, and save labor and time costs.

9. Strong scalability: The design and structure of the manipulator exhibit scalability, allowing for upgrades and modifications based on actual needs, catering to production requirements at different stages.

10. Environmental protection and energy conservation: The automation of the manipulator reduces energy consumption, mitigating its impact on the environment and meeting the requirements of sustainable development.

Summary:

The five-axis servo lateral movement dual-arm two-section manipulator is an automated device featuring high precision, high efficiency, and strong flexibility. Its features include five-axis servo drive, lateral movement structure, dual-arm design, two-section structure, and programmable control. The product's advantages lie in high precision operation, efficient production, strong flexibility, high stability and reliability, easy programming and adjustment, improved safety, reduced labor intensity, cost savings, strong scalability, and environmental protection and energy conservation. Whether in precision machining or assembly fields, the five-axis servo lateral movement dual-arm two-section manipulator can bring significant benefits and competitive advantages to enterprises.

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى