Product Advantages:

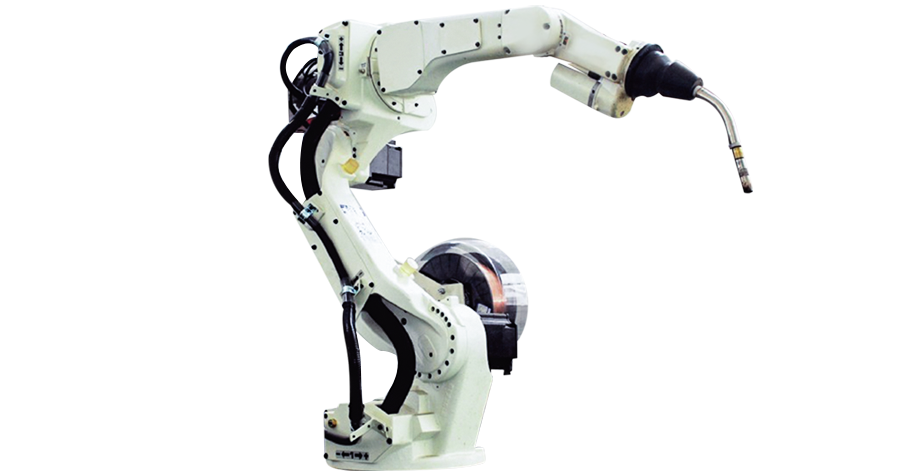

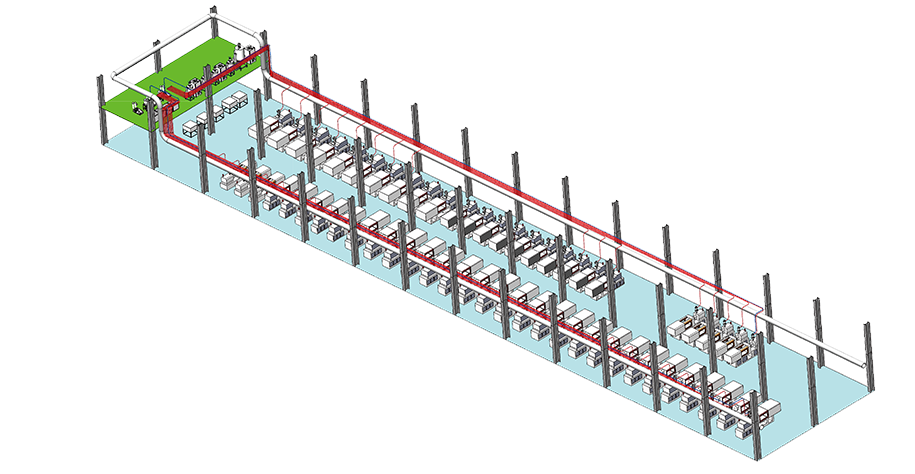

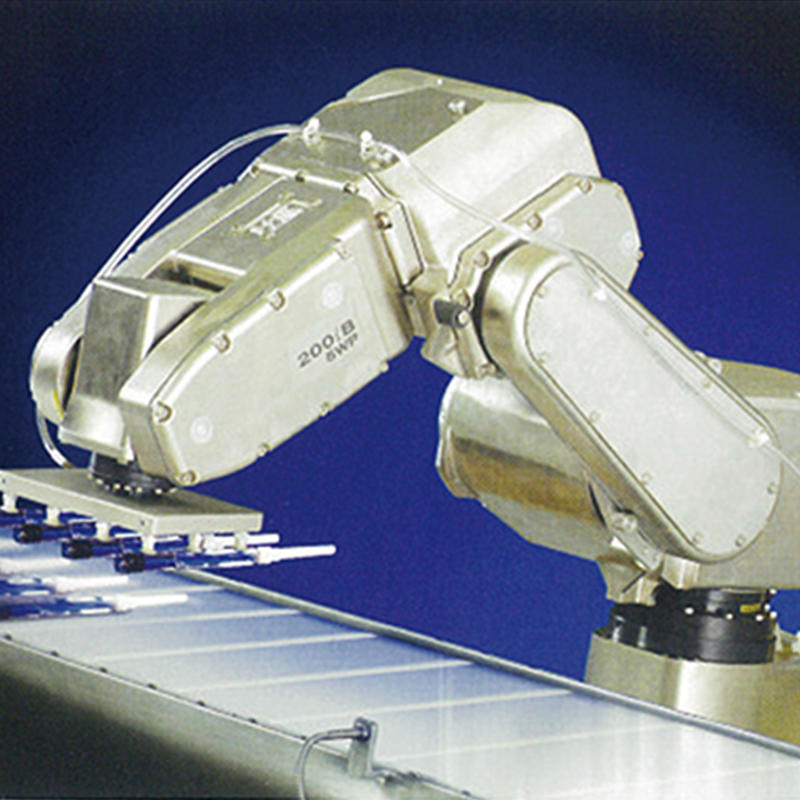

1. Improved production efficiency: The jigs in this frame series can automatically complete operations such as picking, assembly, and placing during the injection molding process, greatly improving production efficiency. Compared to traditional manual operations, robotic jigs can work continuously without being limited by time and manpower.

2. Reduced labor costs: Using this frame series of jigs can reduce the demand for human resources. Machinery arms can replace manual labor for repetitive and tedious operations, saving labor costs and improving the competitiveness of the enterprise.

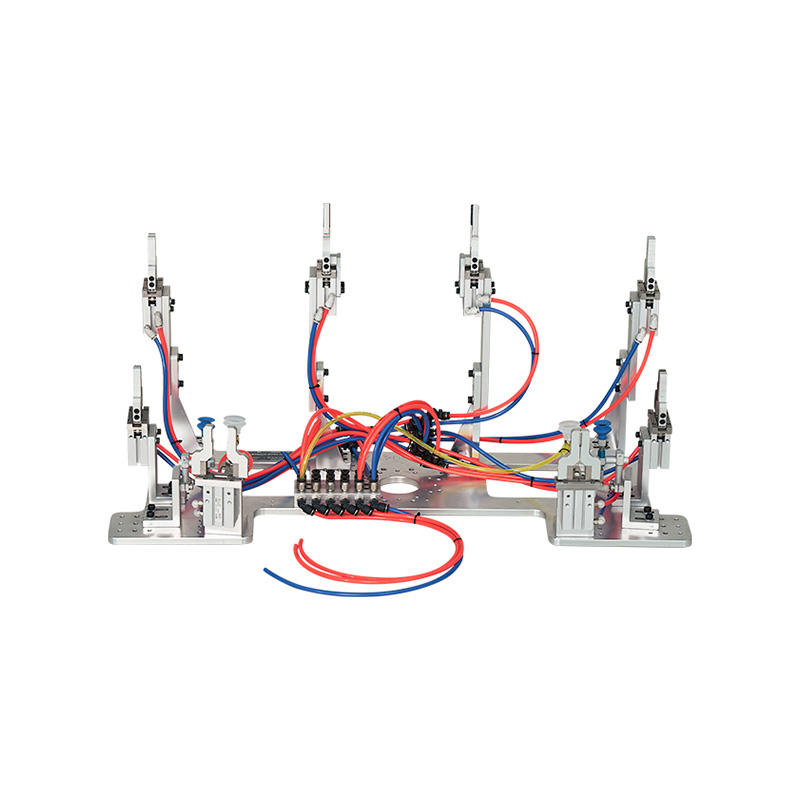

3. Improved product quality: The jigs in this frame series have high precision and stability, ensuring accuracy and consistency during the injection molding process. By reducing interference from human factors, product quality and consistency can be improved.

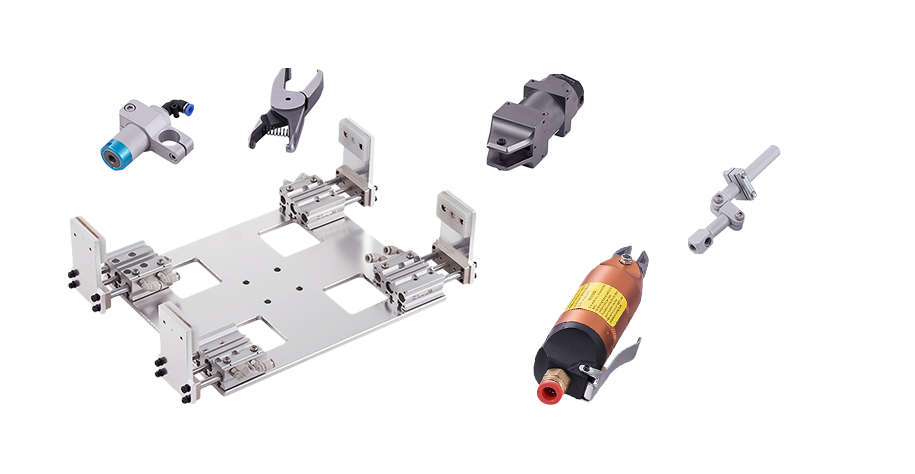

4. Flexibility to adapt to different needs: The jigs in this frame series have multiple different functions and specifications, adaptable to various types and sizes of injection molding machines. Whether it is a single-axis or multi-axis injection molding machine, this frame series of jigs can be used for operation, improving production flexibility and adaptability.

5. Reduced energy consumption: The jigs in this frame series are designed with optimization to reduce energy consumption during the injection molding process. By reducing unnecessary movements and energy waste, production costs can be reduced, improving the economic benefits of the enterprise.

6. Improved working environment: The jigs in this frame series can replace manual labor for dangerous operations, improving the safety of the working environment. Machinery arms can work in harsh environments such as high temperatures, high pressures, and toxic gases, protecting the safety of operators.

7. Easy maintenance and upkeep: The jigs in this frame series have a simple design, making them easy to disassemble and clean. Each component can be replaced individually, reducing maintenance time and costs. At the same time, the durability and reliability of the jigs also reduce the difficulty of maintenance and upkeep.

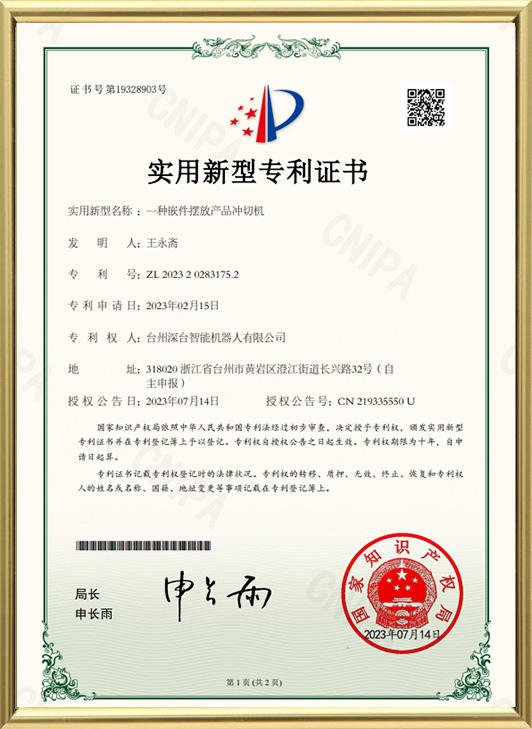

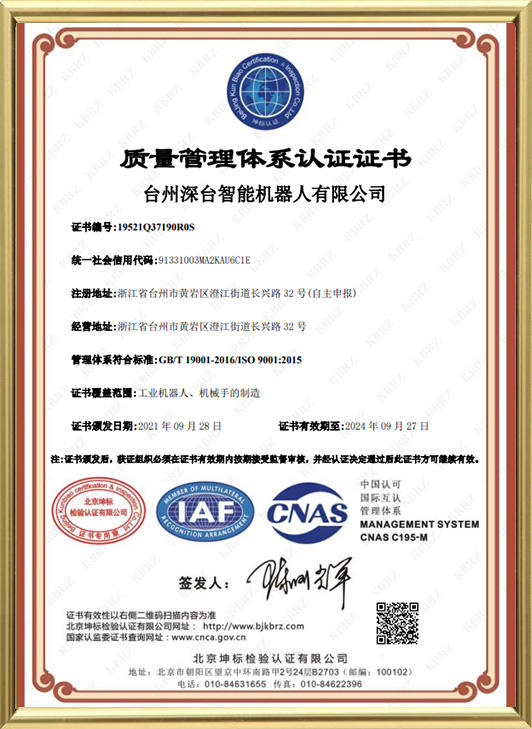

8. Enhanced corporate image: Using this frame series of jigs can enhance the corporate image and competitiveness of the enterprise. Robotic jigs represent the advanced level of modern manufacturing technology, showcasing the company's emphasis on technological innovation and production efficiency.

Summary:

The injection molding machine dedicated robotic jig framework series has features such as high precision, versatility, energy efficiency, safety, reliability, ease of maintenance, etc. Its advantages include improved production efficiency, reduced labor costs, improved product quality, flexibility to adapt to different needs, reduced energy consumption, improved working environment, easy maintenance and upkeep, and enhanced corporate image. These characteristics and advantages make this frame series of jigs an ideal choice for injection molding machine operations, bringing higher production efficiency and economic benefits to the enterprise.

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى